STUDY ABSTRACT

This study was conducted to compare and contrast the various characteristics of Polystone P solid polypropylene sheet, 40mm twin wall sheet and Polystone P CUBx 57mm twin wall sheet in the fabrication of rectangular plastic tanks.

At the end of this study, the results will demonstrate that compared to solid PP sheet and 40mm twin wall sheet, the use of Polystone P CubX in the fabrication of rectangular plastic tanks, from medium sizes (4 to 7m long) and larger, will have:

- A lower manufacturing cost

- Reduced manufacturing times

- Less steel reinforcement requirements

- Lower Tank Weight

- Have lower total costs

TEST SCENARIO

This detailed analysis was conducted on a tank with the following specifications:

- 6000 mm L x 2500 mm W x 1800 mm H

- No nozzles

- Stored liquid – Water

- Temperature - 30º C

- Thermoplastic – Polypropylene

- Design Life – 15 years

The tanks were designed to comply with the German standard DVS 2205, which has been adopted in Australia and New Zealand. In all cases, additional steel reinforcement in the form of RHS (Rectangular Hollow Section) was required to meet the requirements of DVS 2205.

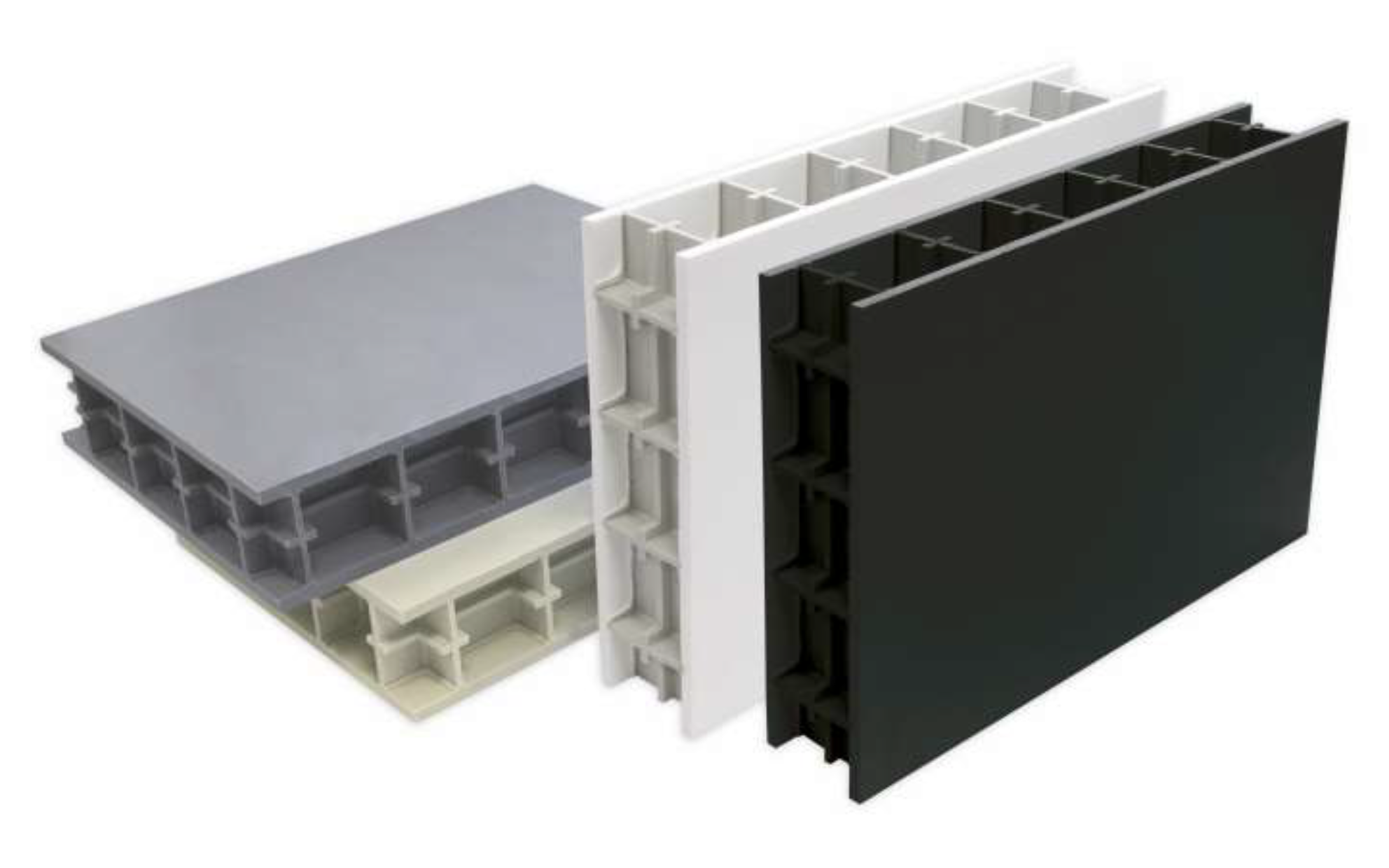

SHEETS FORMATS TESTED

Solid Sheet

Polystone P Homopolymer Polypropylene

40mm Twinwall Sheet

Homopolymer Polypropylene

57mm Twinwall Sheet

Polystone P CubX Homopolymer Polypropylene

RESULTS

The analysis of the labour time, material requirements (both plastic and steel), weight and all associated costs were conducted by an independent plastic tank fabricator that has experience in manufacturing tanks from all material formats, as well as having manufacturing equipment that is suitable for all material formats.

COST COMPARISON

Even though the plastic material cost is not significantly different for all three plastic material formats, as the plastic material sheet stiffness increases (see Figure 3), there is a reduction of steel reinforcement that is required (see Figure 4), where Polystone P CubX requires 21% less steel reinforcement than the 40mm thick twin wall tank, and 28% less steel reinforcement than 25mm solid sheet tank.

Therefore, in addition to lower steel material costs, there is a significant reduction in the total manufacturing time/cost (see Figure 2) where the Polystone P CubX tank requires 14% less time to manufacture the vessel compared to the 40mm twin wall construction, and 39% less time compared to 25mm solid sheet construction.

All of the above variables contribute to the lower total tank/vessel cost (see figure 1); i.e. the Polystone P CubX tank cost is 10% less than the 40mm Twin Wall vessel, and 26% less than the tank manufactured using 25mm solid sheet.

The higher stiffness of thicker format plastic sheet materials is the reason why there is a significantly lower requirement for steel reinforcement for Polystone P CubX to be able to safely (and complying with the DVS guidelines) to store the same volume of liquid.

WEIGHT COMPARISON

The total weight of the tank is also an important factor, as lower tank weights result in lower shipping costs, as well as contributing to safer, easier, and cheaper installation.

CONCLUSION AND OUTCOME

The dominating factor that allows Polystone P CubX to benefit in all the attributes outlined in this white paper is the thickness of the sheet format.

To expand on this point, rectangular tank walls need to resist deflection under load (liquid pressure) to safely operate and meet the requirements of the DVS guidelines. Resistance to deflection is directly related to the Moment of Inertia of the cross-section of the material, and the thickness contributes to this Moment of Inerta at the rate of Thickness to the Power of three (3), i.e t3 (where t = thickness).

Therefore, as the size of a rectangular tank increases, in length, width and/or height, the benefits, as stated in this case study, of Polystone P CubX increase exponentially.

Summary of savings and reductions of Polystone P CubX compared to 40mm Twin Wall and solid sheet constructions.

| % of Polystone P CubX VS 40mm Twin Wall | % of Polystone P CubX Vs 25mm Solid Sheet | |

|---|---|---|

| Weight | 12% Lighter | 19% Lighter |

| Steel | 21% Less Steel | 28% Less Steel |

| Manufacturing Time | 14% Less Manufacturing Time | 39% Less Manufacturing TIme |

| Total Cost | 10% More Cost-Effective | 26% More Cost-Effective |

It should also be noted that there are other Polystone CubX grades that provide the same benefits.

These grades include:

- Polystone G CubX (PE100 RC) Black – PE100 HDPE

- Polystone G CubX (PE100 RC) UV White – PE100 HDPE

- Polystone P CubX UV White – PP

- Polystone PPs CubX – PP FR