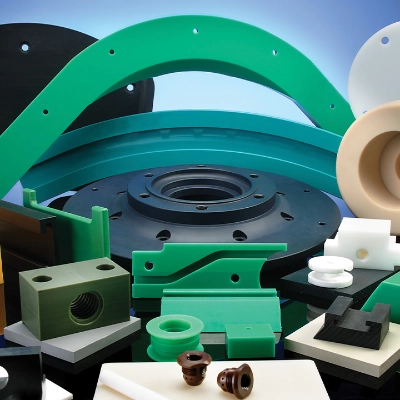

Dotmar Engineering Plastics plays a vital role in supporting the timber and forestry industries by offering solutions that enhance productivity, prolong equipment lifespan, and prioritise worker safety. With a focus on durability, reliability, and practicality, Dotmar remains a trusted partner for businesses seeking to overcome the challenges of operating in these demanding environments.

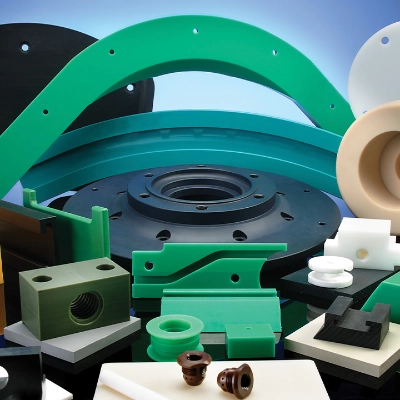

In the non-ideal environment of which the timber and forestry industry operates, Dotmar Engineering Plastics provides tailored solutions that address the unique challenges faced by the market. In an environment where machinery downtime can significantly impact productivity and profitability, Dotmar's engineering plastics offer exceptional wear and abrasion resistance, ensuring continuous operation even in harsh conditions characterized by dust, debris, and wood chips. By minimising maintenance requirements and reducing downtime, these materials play a crucial role in optimising operational efficiency and maximising output.

A key advantage of engineering plastics in the timber and forestry industries lies in their ability to mitigate damage to wood during handling and processing. Components such as guide rollers and j bars, traditionally made of steel, can be replaced with materials like polyurethane, which are gentler on the wood surface. This not only protects the wood from damage but also reduces the frequency of equipment maintenance and repair, leading to cost savings and increased productivity over time.

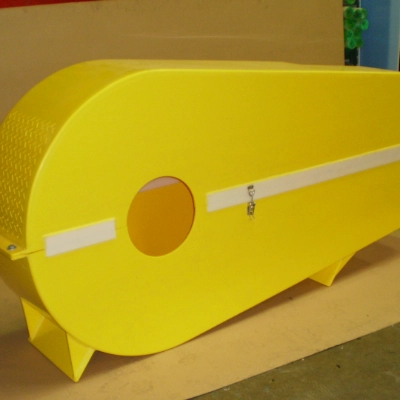

Safety is critical in timber and forestry operations, where workers are often exposed to hazardous conditions and machinery. Dotmar addresses this concern by offering polycarbonate barriers that serve as robust protective measures. Whether used as machine guards, protective windows, or installed on logging trucks, polycarbonate provides a high level of impact resistance, offering peace of mind to workers and minimizing the risk of accidents and injuries. When compared to traditional glass windows, Polycarbonate is 250x more impact resistant.

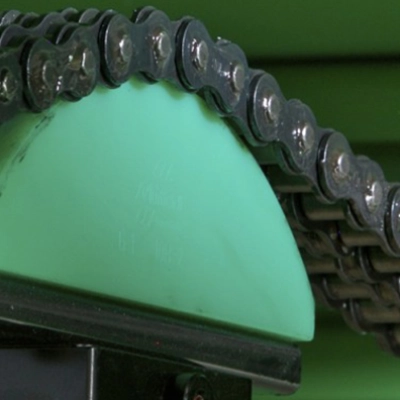

Dotmar's engineering plastics contribute to improved equipment performance and longevity by reducing metal-on-metal contact. This not only decreases wear and tear on machinery but also eliminates the need for lubricants that can attract dirt and wood fibres, leading to increased maintenance requirements and potential equipment damage. By minimising the reliance on lubrication, Dotmar's materials reduce the need for complex sealing systems, further streamlining maintenance processes and enhancing overall reliability.

Download our brochures for further details

Insights

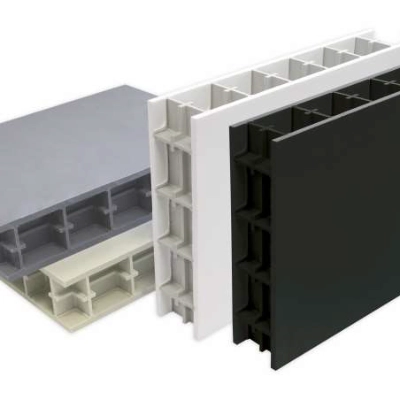

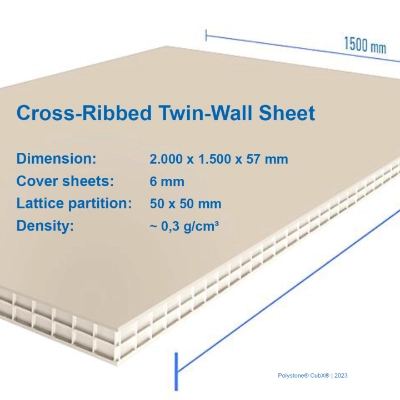

25 Nov 2024 Comparing the technical and commercial benefits of Polystone P CubX for rectangular plastic fabricated tanks and vessels

02 Sept 2024 Cooling Tunnel for Hot Filling Line

25 Nov 2024 Sentinel Boats: Pioneering Defence Durability with Polystone PG100 HDPE

08 Dec 2024 Christmas Closure 2024

08 May 2025 Why Local Manufacturing is the Smarter Choice in 2025

07 Apr 2025 Dotmar Injection Moulding

Dotmar Victoria Receives PACCAR Kenworth Quality Award

09 Feb 2025 Water Absorption of Nylons Pros, Cons and Busting Myths

14 Jan 2025 Tips for Turning and Drilling Engineering Plastics

15 Nov 2024 Significantly Reduce Your Hangup and Carryback to Optimise Your Mining Operations

10 Oct 2024 Why use Engineering Plastic Bearings and Bushes?

29 Sept 2024 Plastic Abbreviations

29 Sept 2024 Plastics Properties Table

29 Sept 2024 Plastics Designing for Thermal Expansion

20 Oct 2024 Antistatic vs Static Dissipative Plastics

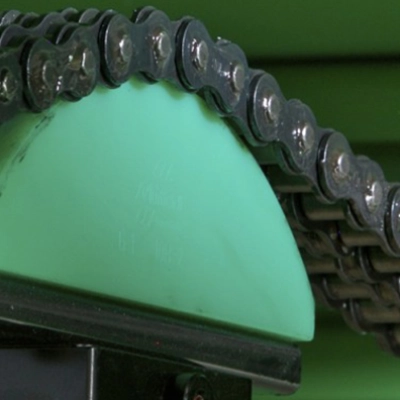

02 Sept 2024 Chain Tension-Right, or Short Chain Life

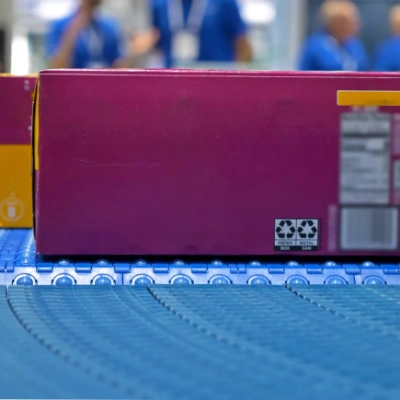

27 Sept 2024 REXNORD curve system with 1540 series MatTop

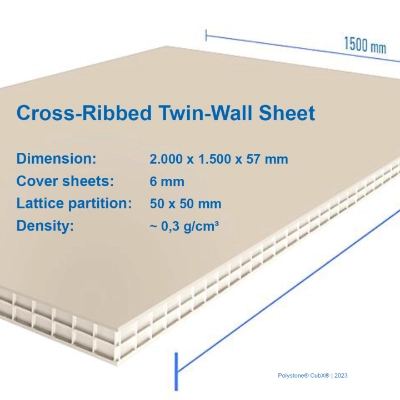

02 Sept 2024 Polystone CubX A Revolution in Rectangular Thermoplastic Tanks

02 Sept 2024 Plastic Technical Tip-Water absorption in Nylon

02 Sept 2024 Performance Pyramid

11 Oct 2024 UHMWPE-Why Does Molecular Weight matter?

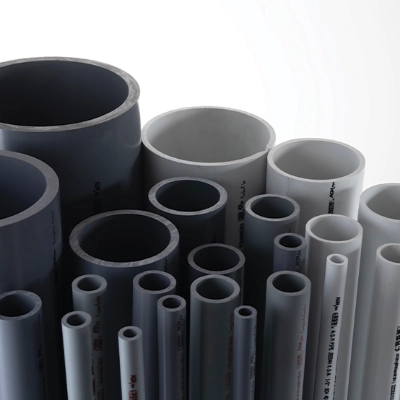

22 June 2025 HDPE vs PP vs PVC

25 Nov 2024 Rochling-Reloop: Leading the Way in Sustainable Plastics

27 Sept 2024 Low Friction Wear Pads

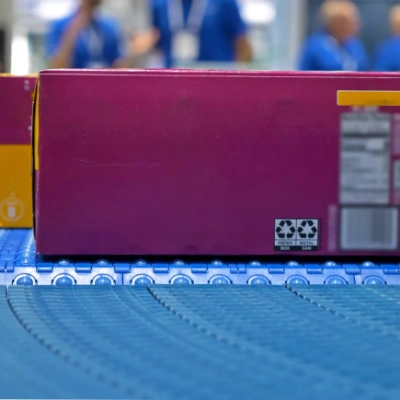

Conveyor Products & Total Solutions for the Food and Beverage Processing & Packaging Industries

03 Dec 2024 Resistawear: Low Friction and Abrasion Resistant Tape

Plastic Machine Guarding Managing the Risks of Plant in the Workplace

HDPE Checkerplate Transom

02 Sept 2024 Cooling Tunnel for Hot Filling Line

Dotmar Victoria Receives PACCAR Kenworth Quality Award

10 Oct 2024 Why use Engineering Plastic Bearings and Bushes?

29 Sept 2024 Plastic Abbreviations

29 Sept 2024 Plastics Properties Table

02 Sept 2024 Chain Tension-Right, or Short Chain Life

02 Sept 2024 Polystone CubX A Revolution in Rectangular Thermoplastic Tanks

11 Oct 2024 UHMWPE-Why Does Molecular Weight matter?

27 Sept 2024 Low Friction Wear Pads

HDPE Checkerplate Transom

09 Feb 2025 Water Absorption of Nylons Pros, Cons and Busting Myths

14 Jan 2025 Tips for Turning and Drilling Engineering Plastics

15 Nov 2024 Significantly Reduce Your Hangup and Carryback to Optimise Your Mining Operations

10 Oct 2024 Why use Engineering Plastic Bearings and Bushes?

29 Sept 2024 Plastic Abbreviations

29 Sept 2024 Plastics Properties Table

29 Sept 2024 Plastics Designing for Thermal Expansion

20 Oct 2024 Antistatic vs Static Dissipative Plastics

27 Sept 2024 REXNORD curve system with 1540 series MatTop

02 Sept 2024 Plastic Technical Tip-Water absorption in Nylon

02 Sept 2024 Performance Pyramid

11 Oct 2024 UHMWPE-Why Does Molecular Weight matter?

22 June 2025 HDPE vs PP vs PVC

25 Nov 2024 Rochling-Reloop: Leading the Way in Sustainable Plastics

Conveyor Products & Total Solutions for the Food and Beverage Processing & Packaging Industries

03 Dec 2024 Resistawear: Low Friction and Abrasion Resistant Tape

Plastic Machine Guarding Managing the Risks of Plant in the Workplace