With more than 20 years of specialised experience collaborating with key water authorities and their primary maintenance contractors, Dotmar offers comprehensive solutions across all water treatment segments.

Dotmar Engineering Plastics plays a crucial role in servicing the grey and black water treatment segment of the water treatment industry by offering a comprehensive range of replacement components and personalised solutions tailored to the specific needs of this sector.

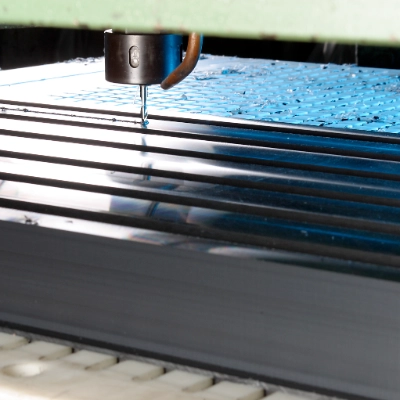

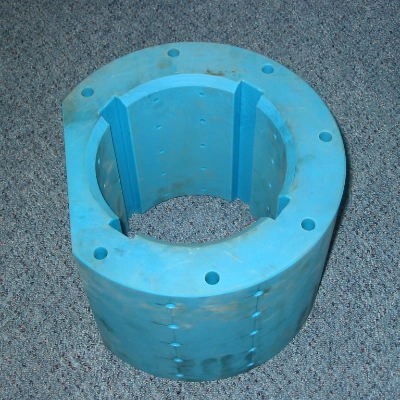

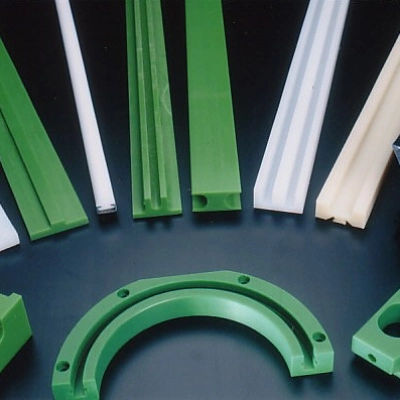

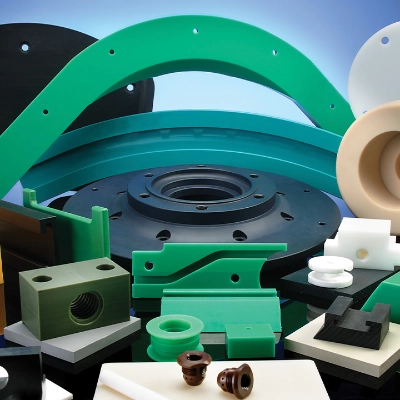

One of the key aspects of Dotmar's service is its provision of replacement components for every stage of the grey and black water treatment process. This includes components for screening, separation, compaction, and dosing, ensuring that water treatment plants have access to the parts they need to maintain efficient and effective operations. Whether a plant requires routine maintenance or a complete refurbishment, Dotmar can provide the necessary components to keep the process running smoothly.

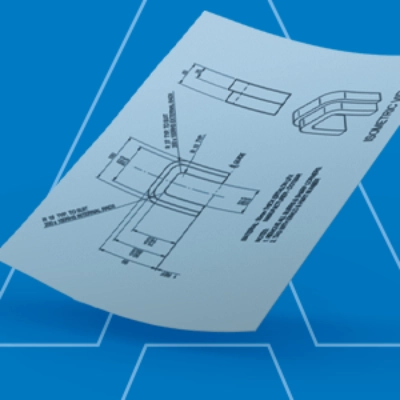

Dotmar emphasises the importance of personalised solutions. By working closely with key stakeholders, Dotmar can develop customised applications that address specific challenges – coupled with superior material selection. This consultative approach ensures that organisations receive the most effective solutions which meet application specifications.

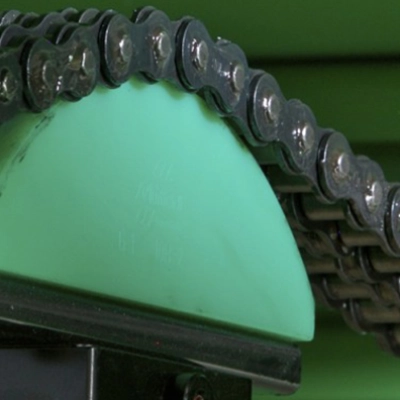

As an example, Polystone 7000, a material renowned for its exceptional wear and abrasion resistance. This is particularly important in the context of grey and black water treatment, where components are exposed to harsh operating conditions and abrasive materials. By utilising materials like Polystone 7000, Dotmar ensures that its components can withstand the rigors of the water treatment process, minimising downtime, and maintenance requirements.

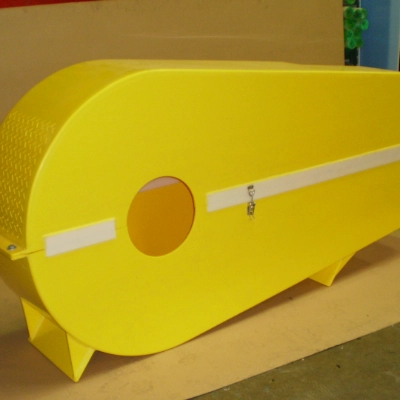

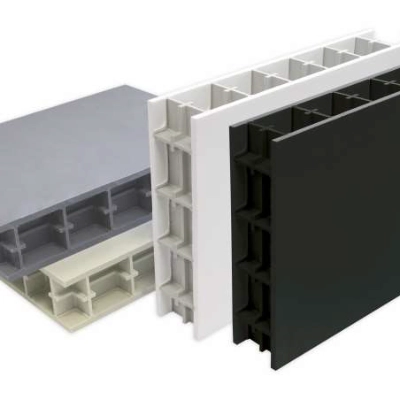

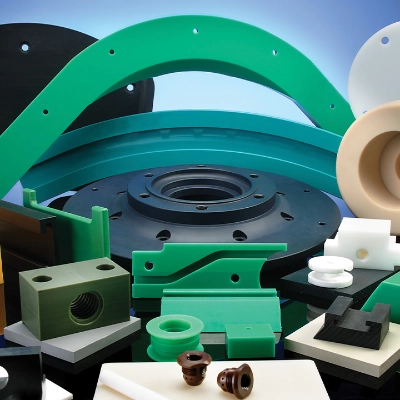

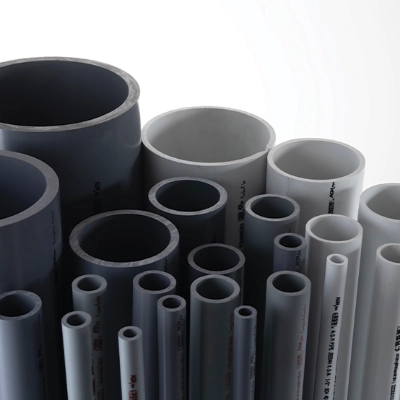

In contrast to steel and other conventional materials, engineering plastics like UHMWPE (Polystone), Nylon (Ertalon), Polypropylene(PP) or HDPE (Polystone P300), stand out for their remarkable corrosion and chemical resistance, a crucial attribute particularly in challenging, high-salinity environments.

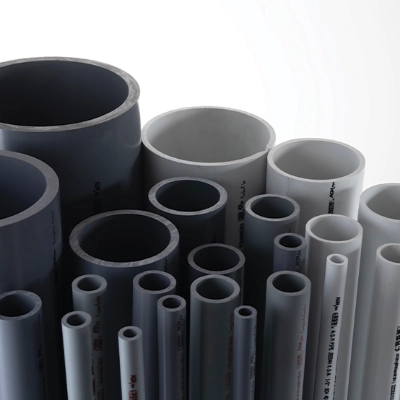

This resilience is of utmost importance in applications involving vessels such as tanks and ducting, where the distinct properties of engineering plastics truly shine. Moreover, Dotmar possesses the expertise to craft bespoke structural components like pipe supports and fittings, enhancing the versatility and tailored functionality of our solutions.

At Dotmar, we prioritise the adherence to drinking water standards, recognising their vital significance. Our range of engineering plastics, including Acetal, Polyethylene (HDPE), and Polypropylene, are meticulously selected to ensure they impart no taste and effectively minimise the risk of contaminants, unlike conventional materials.

Moreover, Dotmar offers a comprehensive supply of materials suitable for various applications, such as fittings for hosing, clamps, and pipes, further reinforcing our commitment to providing safe and reliable solutions for water management.

Download our brochures for further details

Insights

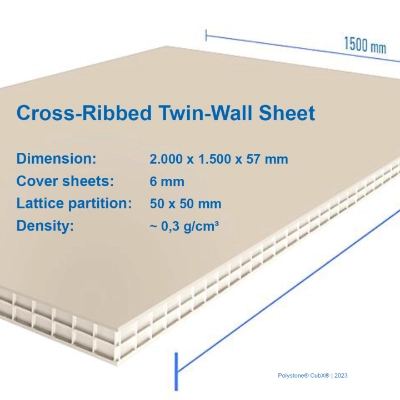

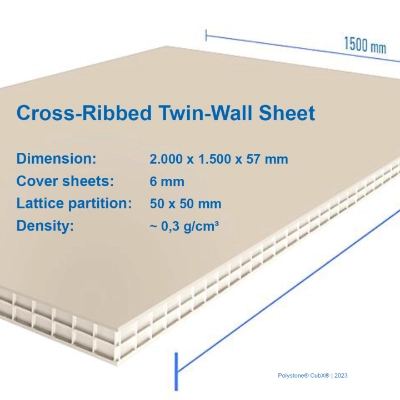

25 Nov 2024 Comparing the technical and commercial benefits of Polystone P CubX for rectangular plastic fabricated tanks and vessels

02 Sept 2024 Cooling Tunnel for Hot Filling Line

25 Nov 2024 Sentinel Boats: Pioneering Defence Durability with Polystone PG100 HDPE

08 Dec 2024 Christmas Closure 2024

08 May 2025 Why Local Manufacturing is the Smarter Choice in 2025

07 Apr 2025 Dotmar Injection Moulding

Dotmar Victoria Receives PACCAR Kenworth Quality Award

09 Feb 2025 Water Absorption of Nylons Pros, Cons and Busting Myths

14 Jan 2025 Tips for Turning and Drilling Engineering Plastics

15 Nov 2024 Significantly Reduce Your Hangup and Carryback to Optimise Your Mining Operations

10 Oct 2024 Why use Engineering Plastic Bearings and Bushes?

29 Sept 2024 Plastic Abbreviations

29 Sept 2024 Plastics Properties Table

29 Sept 2024 Plastics Designing for Thermal Expansion

20 Oct 2024 Antistatic vs Static Dissipative Plastics

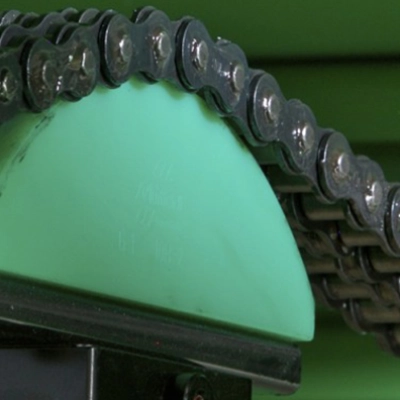

02 Sept 2024 Chain Tension-Right, or Short Chain Life

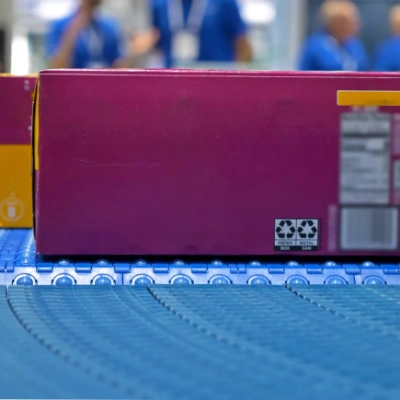

27 Sept 2024 REXNORD curve system with 1540 series MatTop

02 Sept 2024 Polystone CubX A Revolution in Rectangular Thermoplastic Tanks

02 Sept 2024 Plastic Technical Tip-Water absorption in Nylon

02 Sept 2024 Performance Pyramid

11 Oct 2024 UHMWPE-Why Does Molecular Weight matter?

22 June 2025 HDPE vs PP vs PVC

25 Nov 2024 Rochling-Reloop: Leading the Way in Sustainable Plastics

27 Sept 2024 Low Friction Wear Pads

Conveyor Products & Total Solutions for the Food and Beverage Processing & Packaging Industries

03 Dec 2024 Resistawear: Low Friction and Abrasion Resistant Tape

Plastic Machine Guarding Managing the Risks of Plant in the Workplace

HDPE Checkerplate Transom

02 Sept 2024 Cooling Tunnel for Hot Filling Line

Dotmar Victoria Receives PACCAR Kenworth Quality Award

10 Oct 2024 Why use Engineering Plastic Bearings and Bushes?

29 Sept 2024 Plastic Abbreviations

29 Sept 2024 Plastics Properties Table

02 Sept 2024 Chain Tension-Right, or Short Chain Life

02 Sept 2024 Polystone CubX A Revolution in Rectangular Thermoplastic Tanks

11 Oct 2024 UHMWPE-Why Does Molecular Weight matter?

27 Sept 2024 Low Friction Wear Pads

HDPE Checkerplate Transom

09 Feb 2025 Water Absorption of Nylons Pros, Cons and Busting Myths

14 Jan 2025 Tips for Turning and Drilling Engineering Plastics

15 Nov 2024 Significantly Reduce Your Hangup and Carryback to Optimise Your Mining Operations

10 Oct 2024 Why use Engineering Plastic Bearings and Bushes?

29 Sept 2024 Plastic Abbreviations

29 Sept 2024 Plastics Properties Table

29 Sept 2024 Plastics Designing for Thermal Expansion

20 Oct 2024 Antistatic vs Static Dissipative Plastics

27 Sept 2024 REXNORD curve system with 1540 series MatTop

02 Sept 2024 Plastic Technical Tip-Water absorption in Nylon

02 Sept 2024 Performance Pyramid

11 Oct 2024 UHMWPE-Why Does Molecular Weight matter?

22 June 2025 HDPE vs PP vs PVC

25 Nov 2024 Rochling-Reloop: Leading the Way in Sustainable Plastics

Conveyor Products & Total Solutions for the Food and Beverage Processing & Packaging Industries

03 Dec 2024 Resistawear: Low Friction and Abrasion Resistant Tape

Plastic Machine Guarding Managing the Risks of Plant in the Workplace