Dotmar Engineering Plastics plays a vital role in supporting the timber and forestry industries by offering solutions that enhance productivity, prolong equipment lifespan, and prioritise worker safety. With a focus on durability, reliability, and practicality, Dotmar remains a trusted partner for businesses seeking to overcome the challenges of operating in these demanding environments.

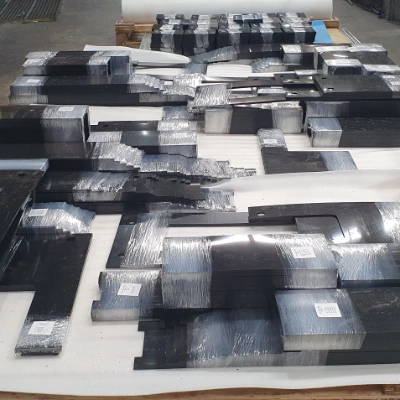

Dotmar Engineering Plastics offer ideal solutions for caravan manufacturers, particularly in interior fitouts where weight reduction and durability are critical concerns. Traditional materials like wood are susceptible to rotting, especially in moist conditions encountered during caravan use. Dotmar's rot-resistant plastics, such as Foamlite and Marinetec, outperform wood by providing long-lasting durability in environments prone to moisture exposure. This durability ensures caravan interiors remain free from rot, mould, and bacteria, enhancing both longevity and hygiene standards.

Dotmar's plastics offer additional benefits beyond durability. Despite being comparable in weight to wood, they impose no further weight penalties on the caravan. Additionally, their elasticity provides noise and vibration dampening benefits, enhancing the comfort of occupants during travel. By choosing Dotmar's engineering plastics for interior fitouts, caravan manufacturers can offer lightweight, resilient, and comfortable living spaces that withstand the rigors of travel and provide lasting satisfaction to customers.

Featured applications

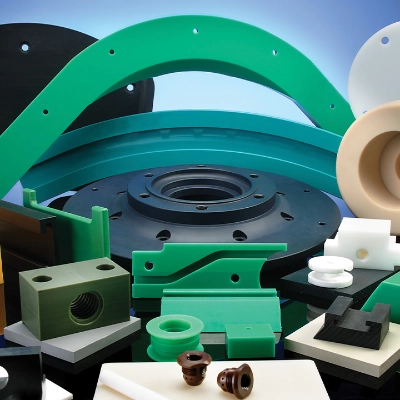

Dotmar Engineering Plastics offer tailored solutions to address the key challenges faced by trucks and buses in maximising payload capacity and minimising maintenance. By leveraging lightweight materials with superior wear resistance compared to traditional options like steel, Dotmar enables significant weight reduction while ensuring durability in components exposed to constant wear and friction, such as bearings, bushes, and wear pads.

One of the critical issues in trucking is carry back, the leftover material sticking to the truck's lining. Dotmar's Matrox Linings provide an effective solution, reducing carry back by up to 20%, thereby ensuring maximum productivity for each and every load.

For moving components like turn-tables and fifth wheels, Dotmar's engineering plastics such as Polystone 7000 AST and Polystone Ultra offer a compelling alternative to steel. With their low coefficient of friction, these plastics provide a slippery surface, facilitating smoother pivoting for trailers and improving manoeuvrability on the road.

In addition to these specialised applications, Dotmar's engineering plastics find diverse uses in truck and bus equipment. For instance, Nylon tarp Bo Rods offer flexibility combined with sufficient stiffness to support the weight of the tarp, ensuring reliable performance in various weather conditions, and loading scenarios.

Featured applications

Dotmar Engineering Plastics offers indispensable solutions for the marine industry, addressing the unique challenges posed by saltwater exposure, UV radiation, corrosion, and wear.

In the harsh marine environment, where saltwater can wreak havoc on components, materials must exhibit exceptional resistance to corrosion, erosion, and wear. Dotmar's engineering plastics excel in meeting these demands, offering unparalleled durability and longevity.

One critical concern in marine applications is galvanic corrosion, caused by electrolysis in saltwater. Dotmar's high-density polyethylene (HDPE) serves as an effective insulator, preventing galvanic corrosion of vital marine components like engine mounts, thus ensuring their reliability and longevity.

Additionally, wear and abrasion components such as ball bearings for pulleys, stern shaft bearings, and rudder bearings benefit greatly from the superior properties of engineering plastics like Ertalyte. These materials, with their high strength and resistance to water absorption, offer durability and reliability even in harsh marine conditions where salt, sand, and grit are prevalent.

Dotmar's materials, such as Polystone PG100 (HDPE), revolutionise conventional hull construction for boat manufacturers. Offering superior impact resistance and abrasion tolerance, Polystone PG100 ensures extended service life and reduced maintenance requirements for marine vessels especially when compared to traditional materials such as aluminium and fibreglass. Its positive buoyancy enhances stability, while its resistance to corrosion, electrolysis, and UV radiation ensures long-term reliability. Furthermore, its fouling resistance minimises maintenance efforts, while its ability to undergo in-situ repairs without the need for hot works ensures continuous operation with minimal downtime.

Featured applications

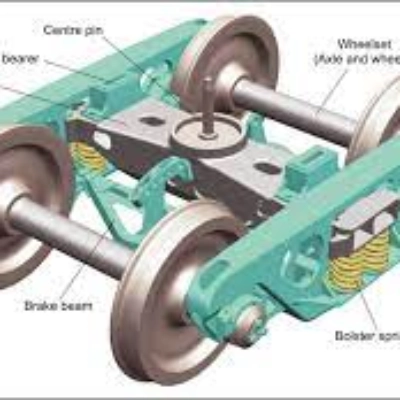

Dotmar Engineering Plastics plays a crucial role in servicing the rail industry by providing tailored solutions that address the unique challenges faced by train carriage manufacturers and track maintenance teams. For carriage makers, Dotmar's focus lies in supplying mechanical parts with exceptional wear and abrasion resistance, such as bushes and wear pads, aimed at reducing maintenance frequency and prolonging the lifespan of components. By replacing metal-on-metal contact with engineered plastics, Dotmar not only eliminates the need for grease and lubricants but also contributes to weight reduction, thus increasing payload capacity and operational efficiency. Moreover, some of Dotmar's range of engineering plastics serve as electrical insulators and isolators, reducing conductivity and offering significant weight savings compared to metal clamps, particularly when utilising materials like Polyethylene. Additionally, Dotmar provides materials compliant with standards like EN45545-2 for fire retardancy and anti-static properties, ensuring safety and reliability in rail applications.

In railway track maintenance, Dotmar's HDPE Polystone 300 H-pads play a vital role in enhancing track performance and longevity. By replacing metal track pads with HDPE H-pads, Dotmar reduces noise levels, improves vibration dampening, and minimises abrasive erosion of concrete sleepers. These H-pads also offer UV resistance, preventing deterioration due to exposure to sunlight, and are immune to rotting and corrosion, ensuring long-term reliability. Additionally, Dotmar's HDPE Polystone 300 turnout plates provide low friction and high wear resistance, essential characteristics for turnout plates to maintain smooth operation over time.

Download our brochures for further details

Insights

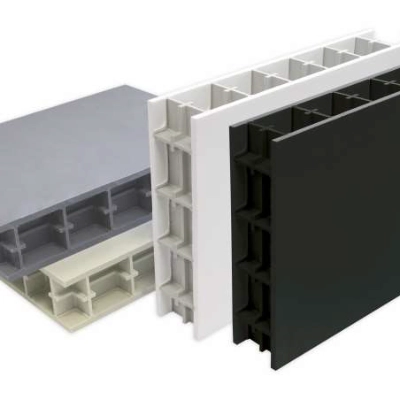

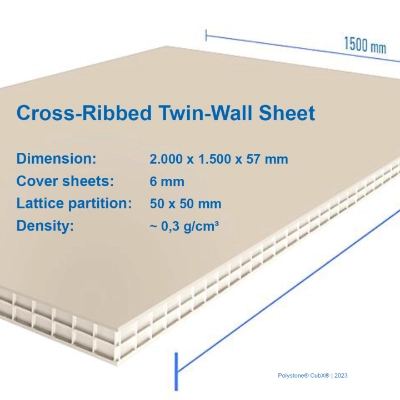

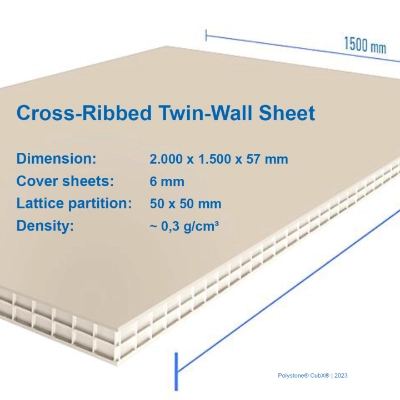

25 Nov 2024 Comparing the technical and commercial benefits of Polystone P CubX for rectangular plastic fabricated tanks and vessels

02 Sept 2024 Cooling Tunnel for Hot Filling Line

25 Nov 2024 Sentinel Boats: Pioneering Defence Durability with Polystone PG100 HDPE

08 Dec 2024 Christmas Closure 2024

08 May 2025 Why Local Manufacturing is the Smarter Choice in 2025

07 Apr 2025 Dotmar Injection Moulding

Dotmar Victoria Receives PACCAR Kenworth Quality Award

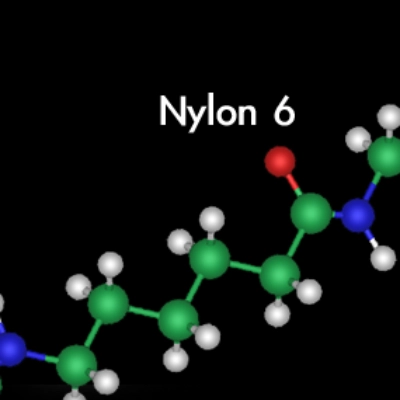

09 Feb 2025 Water Absorption of Nylons Pros, Cons and Busting Myths

14 Jan 2025 Tips for Turning and Drilling Engineering Plastics

15 Nov 2024 Significantly Reduce Your Hangup and Carryback to Optimise Your Mining Operations

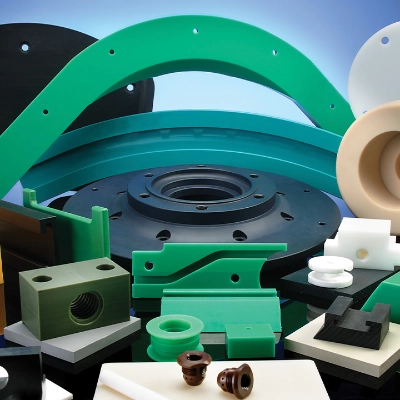

10 Oct 2024 Why use Engineering Plastic Bearings and Bushes?

29 Sept 2024 Plastic Abbreviations

29 Sept 2024 Plastics Properties Table

29 Sept 2024 Plastics Designing for Thermal Expansion

20 Oct 2024 Antistatic vs Static Dissipative Plastics

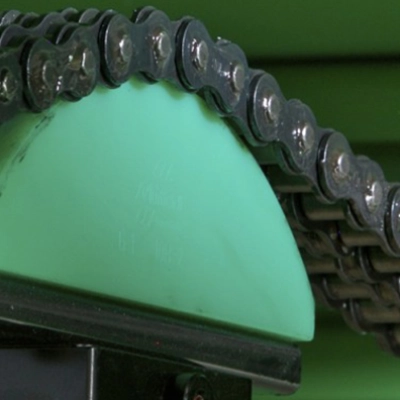

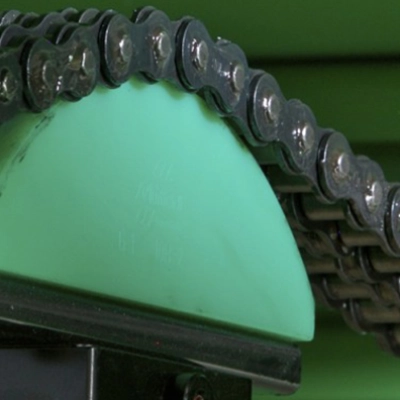

02 Sept 2024 Chain Tension-Right, or Short Chain Life

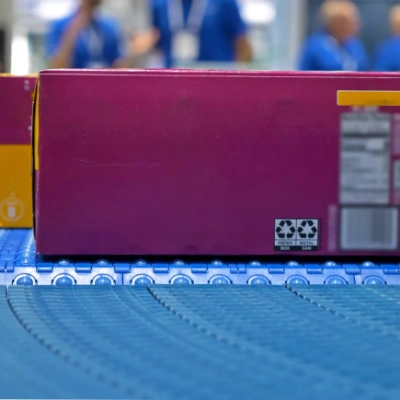

27 Sept 2024 REXNORD curve system with 1540 series MatTop

02 Sept 2024 Polystone CubX A Revolution in Rectangular Thermoplastic Tanks

02 Sept 2024 Plastic Technical Tip-Water absorption in Nylon

02 Sept 2024 Performance Pyramid

11 Oct 2024 UHMWPE-Why Does Molecular Weight matter?

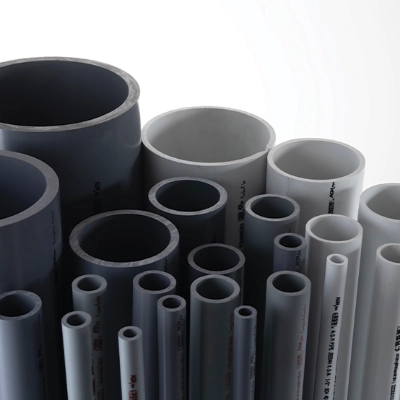

22 June 2025 HDPE vs PP vs PVC

25 Nov 2024 Rochling-Reloop: Leading the Way in Sustainable Plastics

27 Sept 2024 Low Friction Wear Pads

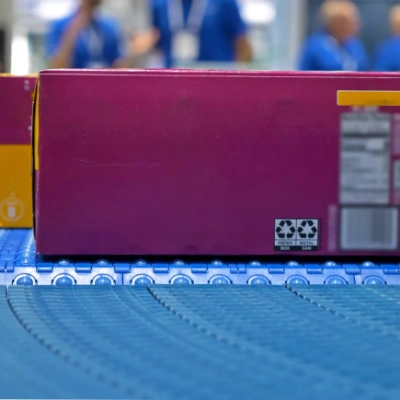

Conveyor Products & Total Solutions for the Food and Beverage Processing & Packaging Industries

03 Dec 2024 Resistawear: Low Friction and Abrasion Resistant Tape

Plastic Machine Guarding Managing the Risks of Plant in the Workplace

HDPE Checkerplate Transom

02 Sept 2024 Cooling Tunnel for Hot Filling Line

Dotmar Victoria Receives PACCAR Kenworth Quality Award

10 Oct 2024 Why use Engineering Plastic Bearings and Bushes?

29 Sept 2024 Plastic Abbreviations

29 Sept 2024 Plastics Properties Table

02 Sept 2024 Chain Tension-Right, or Short Chain Life

02 Sept 2024 Polystone CubX A Revolution in Rectangular Thermoplastic Tanks

11 Oct 2024 UHMWPE-Why Does Molecular Weight matter?

27 Sept 2024 Low Friction Wear Pads

HDPE Checkerplate Transom

09 Feb 2025 Water Absorption of Nylons Pros, Cons and Busting Myths

14 Jan 2025 Tips for Turning and Drilling Engineering Plastics

15 Nov 2024 Significantly Reduce Your Hangup and Carryback to Optimise Your Mining Operations

10 Oct 2024 Why use Engineering Plastic Bearings and Bushes?

29 Sept 2024 Plastic Abbreviations

29 Sept 2024 Plastics Properties Table

29 Sept 2024 Plastics Designing for Thermal Expansion

20 Oct 2024 Antistatic vs Static Dissipative Plastics

27 Sept 2024 REXNORD curve system with 1540 series MatTop

02 Sept 2024 Plastic Technical Tip-Water absorption in Nylon

02 Sept 2024 Performance Pyramid

11 Oct 2024 UHMWPE-Why Does Molecular Weight matter?

22 June 2025 HDPE vs PP vs PVC

25 Nov 2024 Rochling-Reloop: Leading the Way in Sustainable Plastics

Conveyor Products & Total Solutions for the Food and Beverage Processing & Packaging Industries

03 Dec 2024 Resistawear: Low Friction and Abrasion Resistant Tape

Plastic Machine Guarding Managing the Risks of Plant in the Workplace