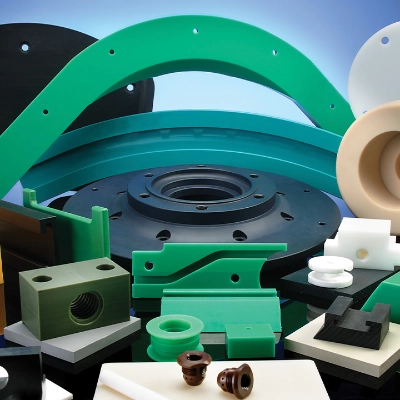

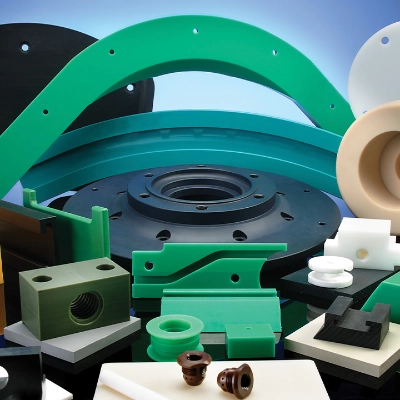

Dotmar Engineering Plastics provides specialised solutions engineered to prevent catastrophic failures and ensure operational integrity. Offering superior durability and reliability compared to traditional materials like fiberglass, Dotmar's engineering plastics streamline production, reduce costs, and meet stringent industry standards.

Dotmar understand that material selection is not merely a matter of preference but a critical decision that can make or break operations. Our range of engineering plastics are produced to withstand the harsh and varied conditions encountered in chemical processing, from varying concentrations to extreme temperatures and durations of exposure.

Comparing to traditional materials like fiberglass, fabricated plastic tanks offer very real advantages. While fiberglass may appear robust, it conceals hidden risks. A minor impact can lead to catastrophic failure, compromising the entire system. The infiltration of harsh chemicals like hydrochloric acid can lead to corrosion of the metal substrate, compromising the entire tank’s integrity. Fabricated polypropylene tanks, on the other hand, ensure complete cleanability and eliminate the risk of corrosion-related failures.

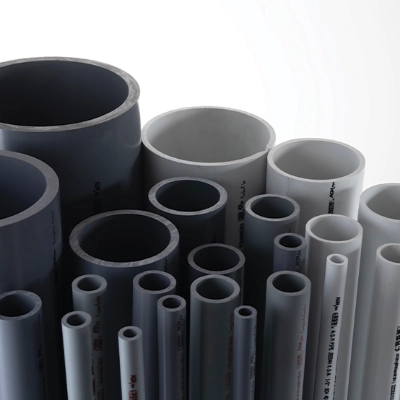

For tanks and pipes with rubber or elastomeric linings, which often necessitate multiple materials and incur higher costs, Dotmar's engineering plastics offer a single-material solution, streamlining production and reducing both labour and material expenses.

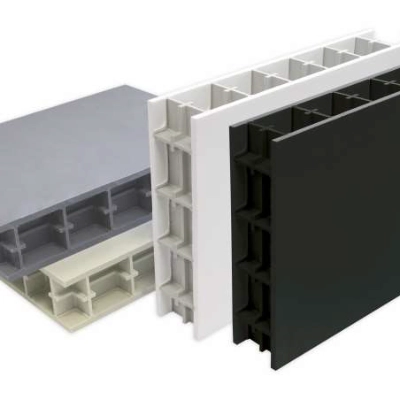

When considering tank construction methods, the distinction between roto-molded and fabricated tanks is crucial. Fabricated tanks offer superior quality, longevity, and chemical resistance compared to their roto-molded counterparts. The controlled manufacturing process allows for precise material application and customisation, ensuring optimal performance in demanding environments. Our commitment to meeting rigorous Australian and DVS standards and leveraging industry-accepted RITA design software ensures your solution is compliant.

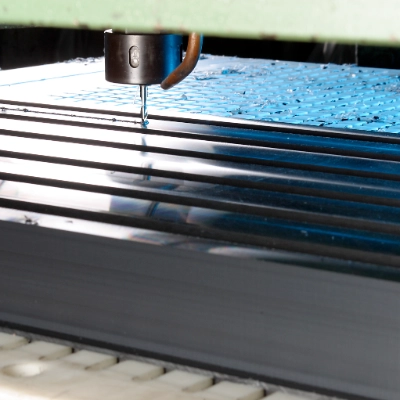

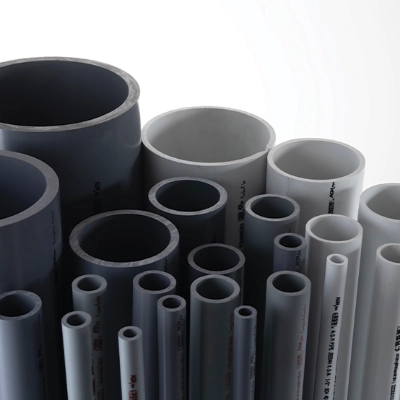

Beyond tanks, Dotmar’s range of engineering plastics can be used in a number of different applications. For example, lined pipes, with materials like PTFE and fluoropolymers providing exceptional resistance to harsh conditions encountered in chemical processing.

Featured applications

Download our brochures for further details

Insights

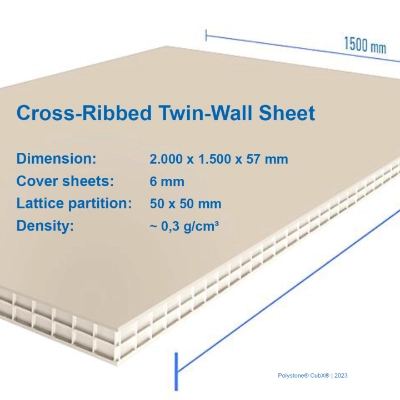

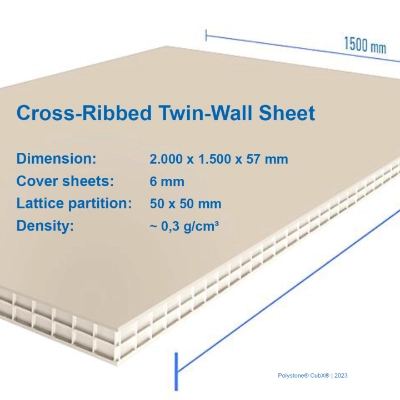

25 Nov 2024 Comparing the technical and commercial benefits of Polystone P CubX for rectangular plastic fabricated tanks and vessels

02 Sept 2024 Cooling Tunnel for Hot Filling Line

25 Nov 2024 Sentinel Boats: Pioneering Defence Durability with Polystone PG100 HDPE

08 Dec 2024 Christmas Closure 2024

08 May 2025 Why Local Manufacturing is the Smarter Choice in 2025

07 Apr 2025 Dotmar Injection Moulding

Dotmar Victoria Receives PACCAR Kenworth Quality Award

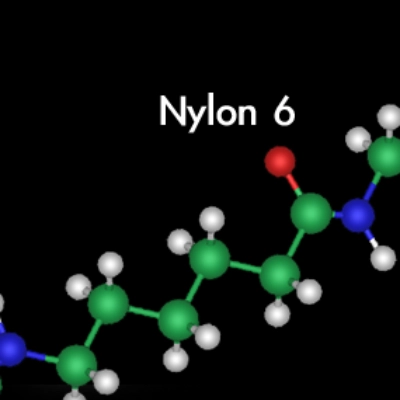

09 Feb 2025 Water Absorption of Nylons Pros, Cons and Busting Myths

14 Jan 2025 Tips for Turning and Drilling Engineering Plastics

15 Nov 2024 Significantly Reduce Your Hangup and Carryback to Optimise Your Mining Operations

10 Oct 2024 Why use Engineering Plastic Bearings and Bushes?

29 Sept 2024 Plastic Abbreviations

29 Sept 2024 Plastics Properties Table

29 Sept 2024 Plastics Designing for Thermal Expansion

20 Oct 2024 Antistatic vs Static Dissipative Plastics

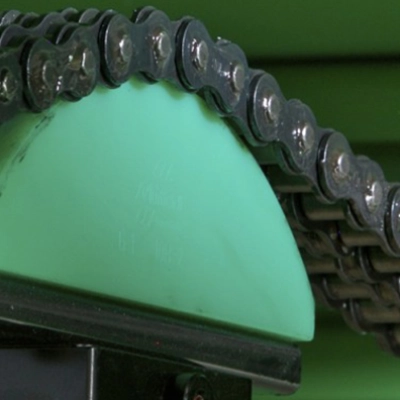

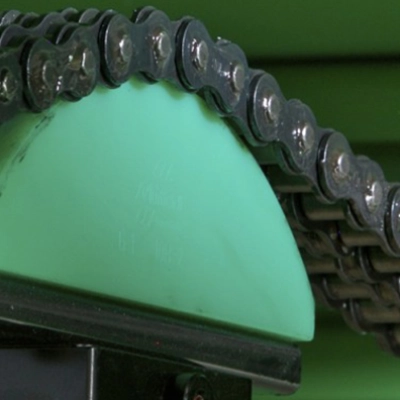

02 Sept 2024 Chain Tension-Right, or Short Chain Life

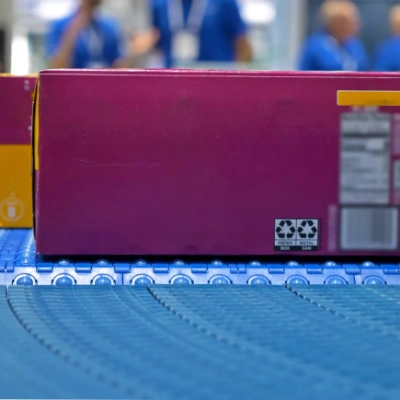

27 Sept 2024 REXNORD curve system with 1540 series MatTop

02 Sept 2024 Polystone CubX A Revolution in Rectangular Thermoplastic Tanks

02 Sept 2024 Plastic Technical Tip-Water absorption in Nylon

02 Sept 2024 Performance Pyramid

11 Oct 2024 UHMWPE-Why Does Molecular Weight matter?

22 June 2025 HDPE vs PP vs PVC

25 Nov 2024 Rochling-Reloop: Leading the Way in Sustainable Plastics

27 Sept 2024 Low Friction Wear Pads

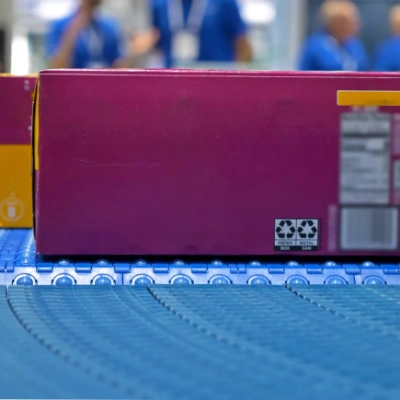

Conveyor Products & Total Solutions for the Food and Beverage Processing & Packaging Industries

03 Dec 2024 Resistawear: Low Friction and Abrasion Resistant Tape

Plastic Machine Guarding Managing the Risks of Plant in the Workplace

HDPE Checkerplate Transom

02 Sept 2024 Cooling Tunnel for Hot Filling Line

Dotmar Victoria Receives PACCAR Kenworth Quality Award

10 Oct 2024 Why use Engineering Plastic Bearings and Bushes?

29 Sept 2024 Plastic Abbreviations

29 Sept 2024 Plastics Properties Table

02 Sept 2024 Chain Tension-Right, or Short Chain Life

02 Sept 2024 Polystone CubX A Revolution in Rectangular Thermoplastic Tanks

11 Oct 2024 UHMWPE-Why Does Molecular Weight matter?

27 Sept 2024 Low Friction Wear Pads

HDPE Checkerplate Transom

09 Feb 2025 Water Absorption of Nylons Pros, Cons and Busting Myths

14 Jan 2025 Tips for Turning and Drilling Engineering Plastics

15 Nov 2024 Significantly Reduce Your Hangup and Carryback to Optimise Your Mining Operations

10 Oct 2024 Why use Engineering Plastic Bearings and Bushes?

29 Sept 2024 Plastic Abbreviations

29 Sept 2024 Plastics Properties Table

29 Sept 2024 Plastics Designing for Thermal Expansion

20 Oct 2024 Antistatic vs Static Dissipative Plastics

27 Sept 2024 REXNORD curve system with 1540 series MatTop

02 Sept 2024 Plastic Technical Tip-Water absorption in Nylon

02 Sept 2024 Performance Pyramid

11 Oct 2024 UHMWPE-Why Does Molecular Weight matter?

22 June 2025 HDPE vs PP vs PVC

25 Nov 2024 Rochling-Reloop: Leading the Way in Sustainable Plastics

Conveyor Products & Total Solutions for the Food and Beverage Processing & Packaging Industries

03 Dec 2024 Resistawear: Low Friction and Abrasion Resistant Tape

Plastic Machine Guarding Managing the Risks of Plant in the Workplace