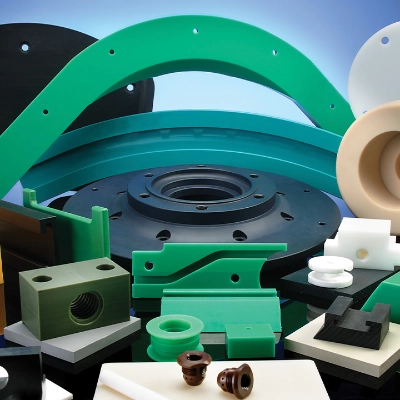

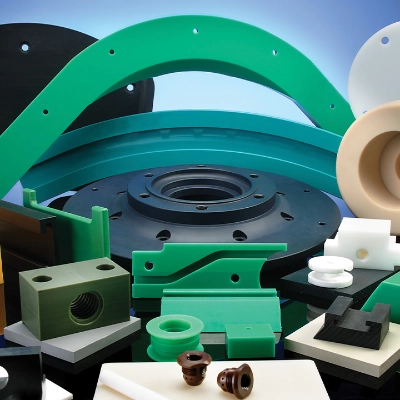

Dotmar offers a comprehensive range of engineering plastics tailored to the demanding needs of the agriculture sector, where resilience in unpredictable and non-ideal environments is paramount. With our wide selection, we provide durable solutions for any application, ensuring enduring performance in even the toughest conditions.

Qualified Engineers and Experienced Specialists: Our team comprises qualified engineers with in-depth expertise in engineering plastics. We offer comprehensive guidance on material selection, leveraging our understanding of material properties and performance characteristics to meet your project specifications precisely. From load capacity calculations for bearings, bushes, rollers, and wire rope sheaves to intricate design considerations for tanks and vessels (RITA), our engineers provide precise insights to optimize performance.

Engineering Calculations and Reports: Dotmar delivers detailed application calculations and reports tailored to your project requirements. Whether you're assessing load capacities or determining resistance factors, our calculations provide the technical foundation necessary for informed decision-making.

Engineering Drawings: Precision is paramount in engineering. Dotmar provides meticulously crafted engineering drawings, ensuring seamless integration of plastics into your designs. Our drawings adhere to industry standards and facilitate accurate implementation, minimising potential errors and streamlining the manufacturing process.

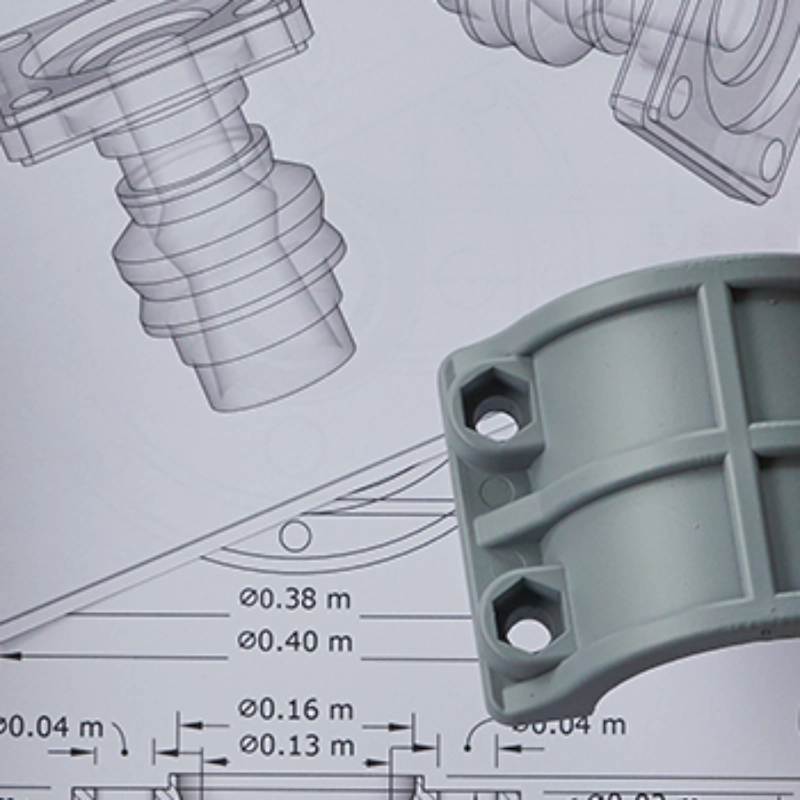

Reverse Engineering and Material Enhancement: Need to improve performance or identify materials? Our reverse engineering services include thorough material identification and targeted recommendations for enhancing functionality. We leverage advanced techniques to analyze material properties, enabling us to optimize designs for superior performance and durability.

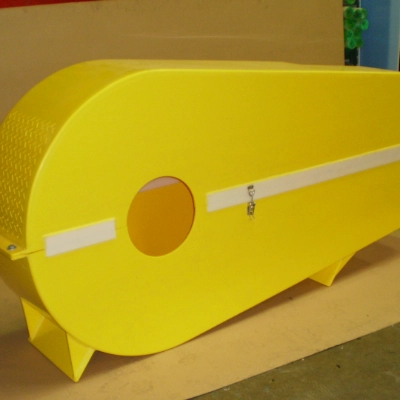

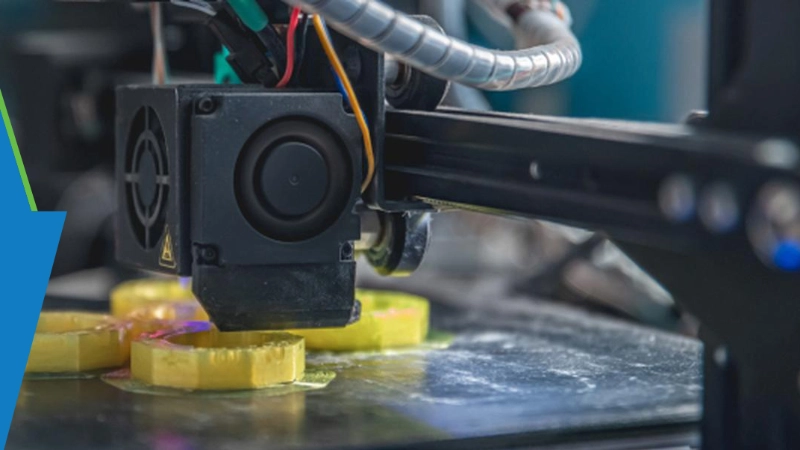

Customised Applications: Every engineering challenge is unique, and our team excels at developing tailored solutions to address your specific needs. Dotmar's expertise transforms plastics into a genuine engineering alternative, offering innovative solutions that meet the demands of even the most complex projects.

ISO 9001 Certification: Dotmar's commitment to quality is underscored by our ISO 9001 certification. This certification validates our adherence to stringent quality management standards, ensuring that our products and services consistently meet or exceed industry expectations.

Comprehensive Manufacturing Support: Dotmar provides end-to-end manufacturing support, offering technical expertise and guidance throughout the project lifecycle. Our advanced manufacturing capabilities enable us to translate concepts into reality efficiently and effectively, ensuring timely delivery without compromising quality.

Download our brochures for further details

Insights

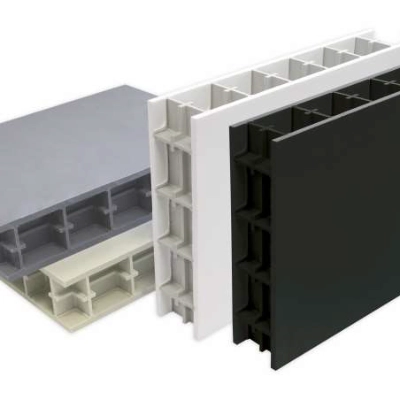

25 Nov 2024 Comparing the technical and commercial benefits of Polystone P CubX for rectangular plastic fabricated tanks and vessels

02 Sept 2024 Cooling Tunnel for Hot Filling Line

25 Nov 2024 Sentinel Boats: Pioneering Defence Durability with Polystone PG100 HDPE

08 Dec 2024 Christmas Closure 2024

08 May 2025 Why Local Manufacturing is the Smarter Choice in 2025

07 Apr 2025 Dotmar Injection Moulding

Dotmar Victoria Receives PACCAR Kenworth Quality Award

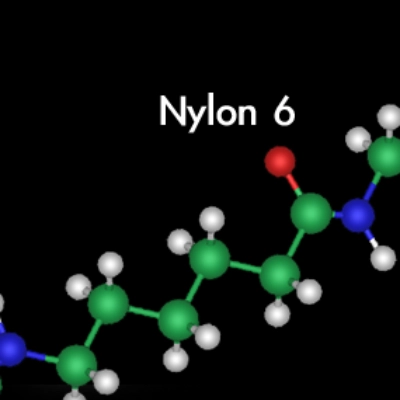

09 Feb 2025 Water Absorption of Nylons Pros, Cons and Busting Myths

14 Jan 2025 Tips for Turning and Drilling Engineering Plastics

15 Nov 2024 Significantly Reduce Your Hangup and Carryback to Optimise Your Mining Operations

10 Oct 2024 Why use Engineering Plastic Bearings and Bushes?

29 Sept 2024 Plastic Abbreviations

29 Sept 2024 Plastics Properties Table

29 Sept 2024 Plastics Designing for Thermal Expansion

20 Oct 2024 Antistatic vs Static Dissipative Plastics

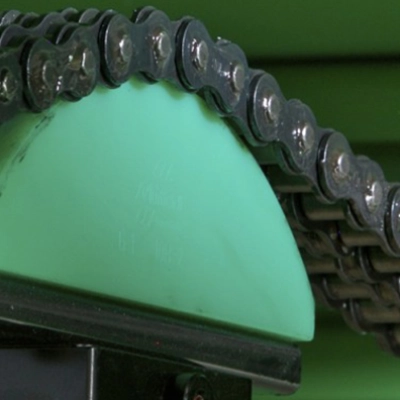

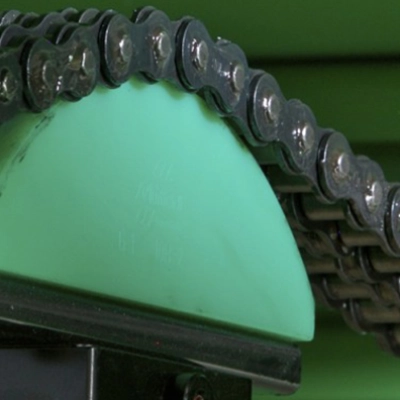

02 Sept 2024 Chain Tension-Right, or Short Chain Life

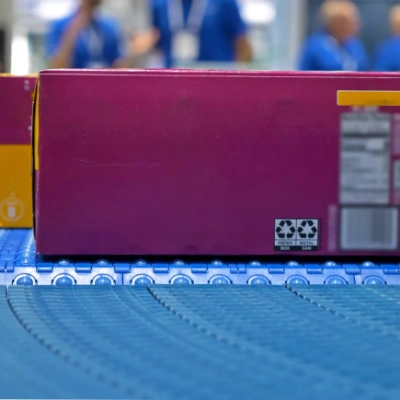

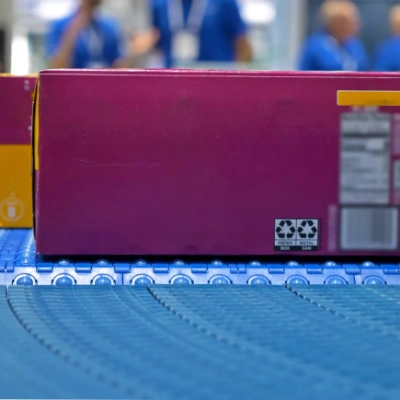

27 Sept 2024 REXNORD curve system with 1540 series MatTop

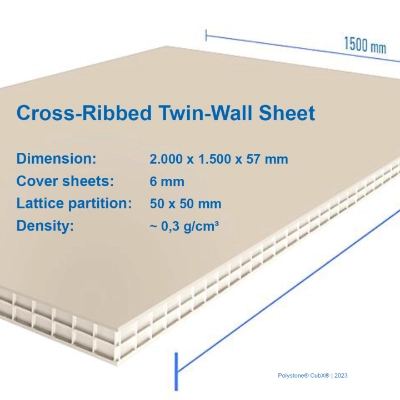

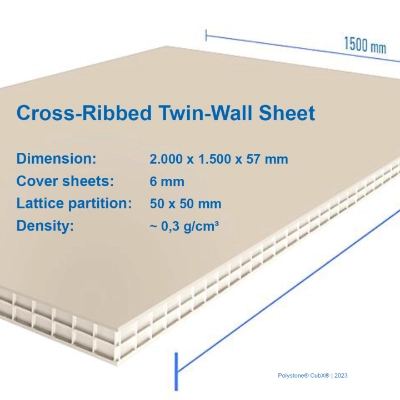

02 Sept 2024 Polystone CubX A Revolution in Rectangular Thermoplastic Tanks

02 Sept 2024 Plastic Technical Tip-Water absorption in Nylon

02 Sept 2024 Performance Pyramid

11 Oct 2024 UHMWPE-Why Does Molecular Weight matter?

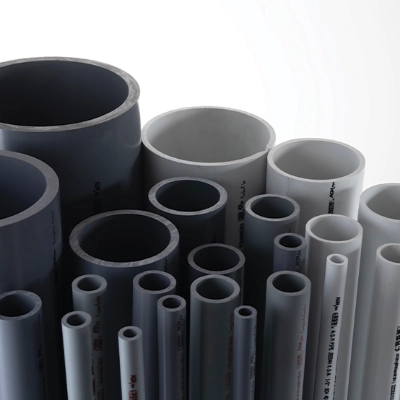

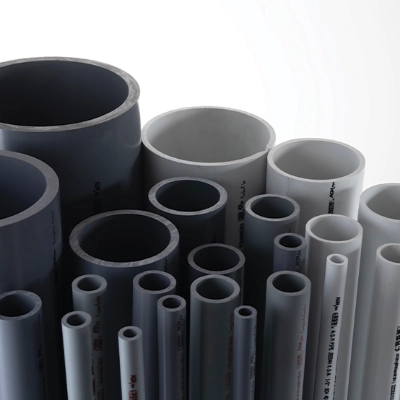

22 June 2025 HDPE vs PP vs PVC

25 Nov 2024 Rochling-Reloop: Leading the Way in Sustainable Plastics

27 Sept 2024 Low Friction Wear Pads

Conveyor Products & Total Solutions for the Food and Beverage Processing & Packaging Industries

03 Dec 2024 Resistawear: Low Friction and Abrasion Resistant Tape

Plastic Machine Guarding Managing the Risks of Plant in the Workplace

HDPE Checkerplate Transom

02 Sept 2024 Cooling Tunnel for Hot Filling Line

Dotmar Victoria Receives PACCAR Kenworth Quality Award

10 Oct 2024 Why use Engineering Plastic Bearings and Bushes?

29 Sept 2024 Plastic Abbreviations

29 Sept 2024 Plastics Properties Table

02 Sept 2024 Chain Tension-Right, or Short Chain Life

02 Sept 2024 Polystone CubX A Revolution in Rectangular Thermoplastic Tanks

11 Oct 2024 UHMWPE-Why Does Molecular Weight matter?

27 Sept 2024 Low Friction Wear Pads

HDPE Checkerplate Transom

09 Feb 2025 Water Absorption of Nylons Pros, Cons and Busting Myths

14 Jan 2025 Tips for Turning and Drilling Engineering Plastics

15 Nov 2024 Significantly Reduce Your Hangup and Carryback to Optimise Your Mining Operations

10 Oct 2024 Why use Engineering Plastic Bearings and Bushes?

29 Sept 2024 Plastic Abbreviations

29 Sept 2024 Plastics Properties Table

29 Sept 2024 Plastics Designing for Thermal Expansion

20 Oct 2024 Antistatic vs Static Dissipative Plastics

27 Sept 2024 REXNORD curve system with 1540 series MatTop

02 Sept 2024 Plastic Technical Tip-Water absorption in Nylon

02 Sept 2024 Performance Pyramid

11 Oct 2024 UHMWPE-Why Does Molecular Weight matter?

22 June 2025 HDPE vs PP vs PVC

25 Nov 2024 Rochling-Reloop: Leading the Way in Sustainable Plastics

Conveyor Products & Total Solutions for the Food and Beverage Processing & Packaging Industries

03 Dec 2024 Resistawear: Low Friction and Abrasion Resistant Tape

Plastic Machine Guarding Managing the Risks of Plant in the Workplace