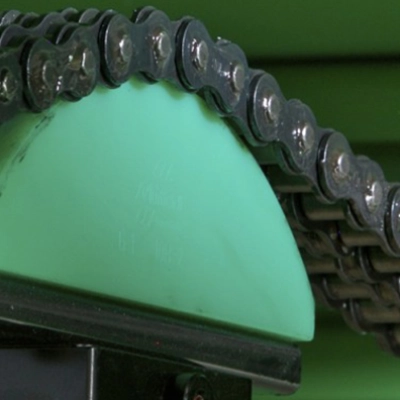

What are Plastic Bogie Wear Parts?

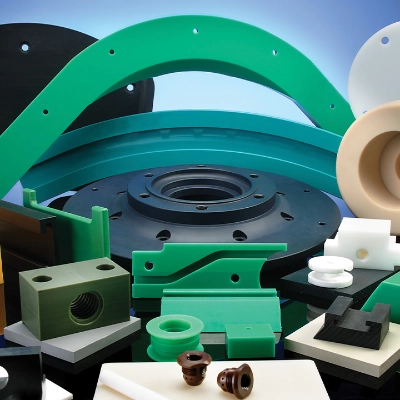

A train bogie is essentially the framework or undercarriage of a rail vehicle that carries the wheels, axles, and suspension system. It is positioned beneath the body of the train and supports its weight. The varies parts that move relative to each other require sacrificial wear parts that are wear resistance and have a low coefficient of friction.

Benefits of Plastic Bushes & Bearings vs Other Bearings

- Eliminating Lubricants – unlike bronze or other metal wear parts, often plastic wear parts, such as Sustamid, can run dry.

- Dirty & dusty conditions – where traditional bearings suffer, plastics can provide maintenance free operation.

- Low Friction – metal-on-metal sliding results in higher friction than plastic-on-metal, and increased wear rates, opposed to the low friction of plastics. Plastics also provide smoother sliding and operation.

- Reduced wear – traditional metal liners result in higher wear of both the counterface and the liner itself and therefore reduced service life.

Dotmar has qualified engineers that can provide direct support with plastic bogie wear parts.