What is a Plastic Conveyor Impact Bed Wear Strip?

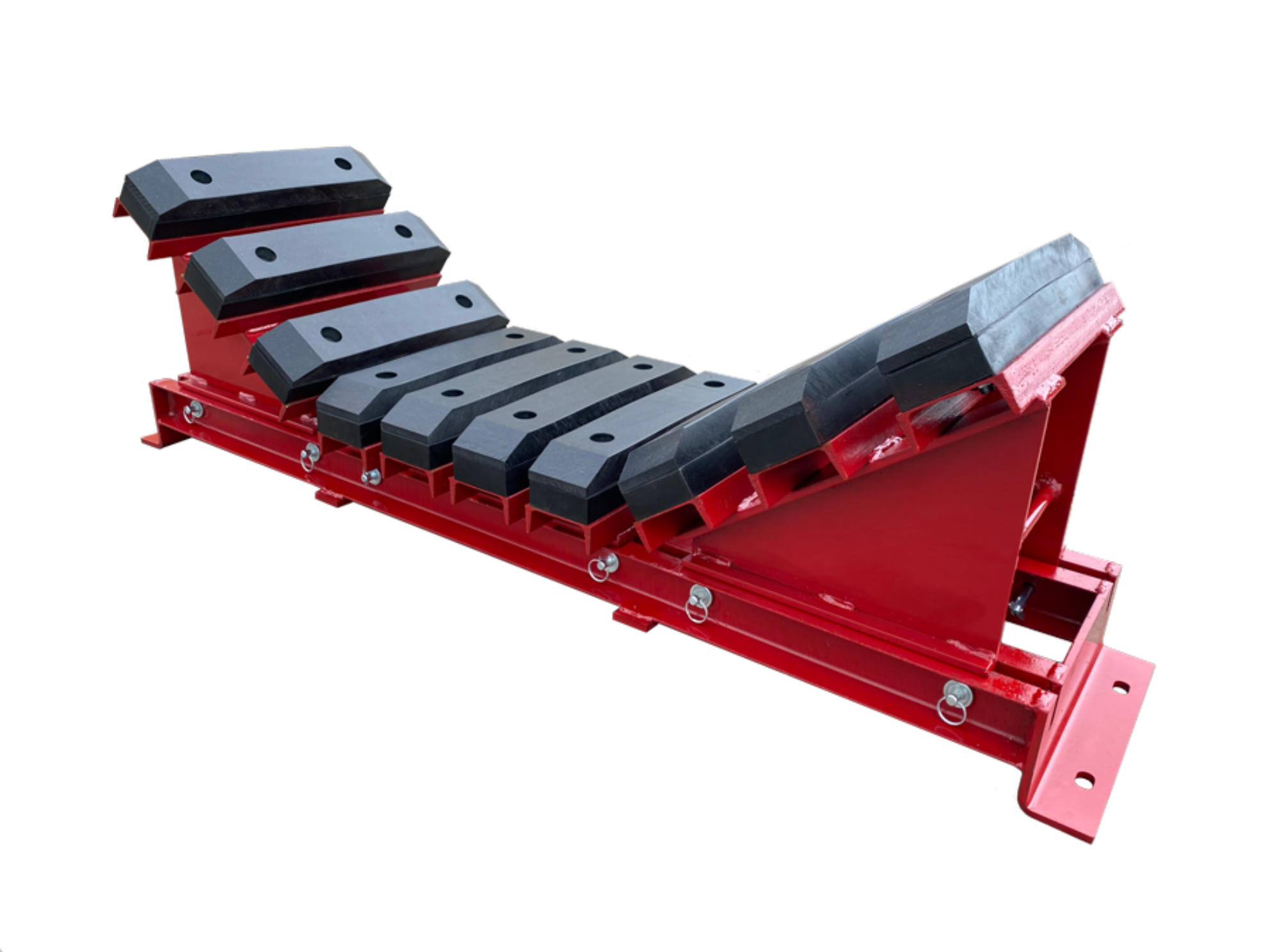

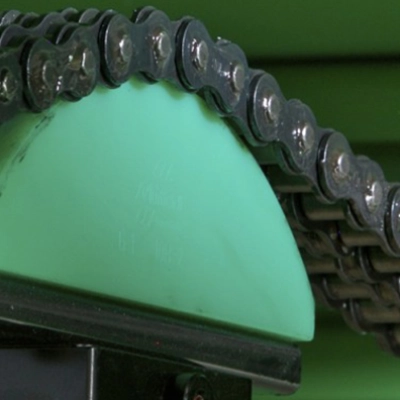

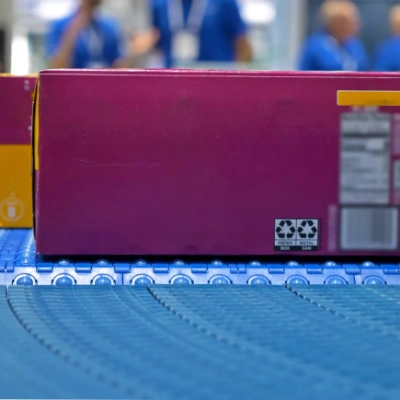

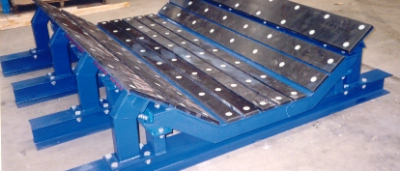

A Conveyor Impact Bed Wear Strip is a component used in conveyor systems to help protect the conveyor belt and extend its lifespan. The Impact Bed is a support mechanism located underneath the conveyor belt at the loading point where materials are dropped onto the belt to absorb the impact energy from the material being loaded onto the belt, reducing the stress on the belt and preventing damage.

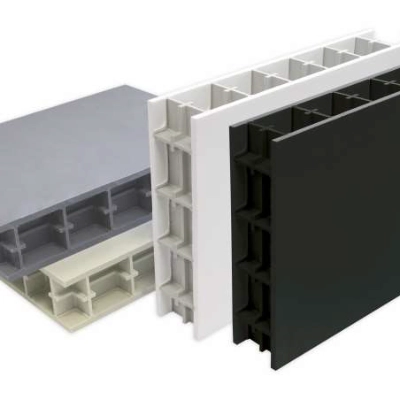

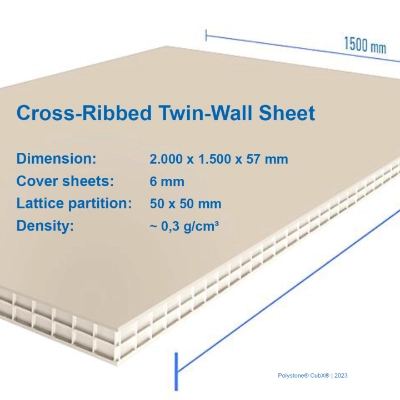

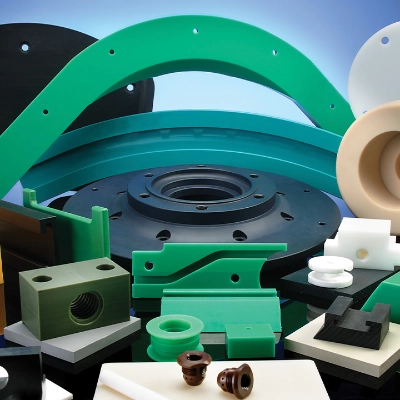

The Wear Strip is a replaceable strip or liner typically made of a durable material such as Polystone 7000. This strip is designed to withstand the friction and abrasion caused by the sliding and impact of the material on the conveyor belt.

Benefits of Plastic Conveyor Impact Bed Wear Strips

- Low Friction – Plastics have a low co-efficient of friction, therefore reducing the drag forces, and energy to drive the conveyor belt, as well as lower loads on the structure.

- Abrasion resistance – materials such as Polystone 7000 AST have superior abrasion resistance, which is imperative for maximizing the wear life of these replacement items.

- High Speed – Specially formulated materials such as Ticomp HVM, has been designed to operate with belts speeds of 6 m/s.

- Reduced wear – In addition to the long service life of plastic wear strips, they also minimise the wear and longevity of the conveyor belt.

- Impact Absorption - The primary purpose of an impact bed is to absorb the impact energy generated when materials are dropped onto the conveyor belt. Plastic wear strips contribute to this by providing a cushioning effect, reducing the force transmitted to the conveyor belt and minimising the risk of damage.

Dotmar has qualified engineers that can provide direct support with plastic conveyor impact bed wear strips.