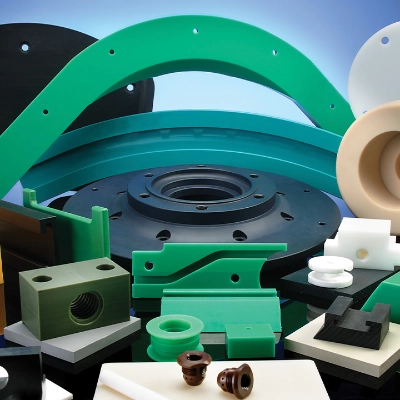

What are Plastic Custom Machined Parts?

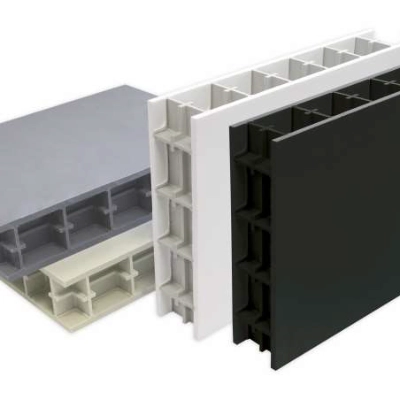

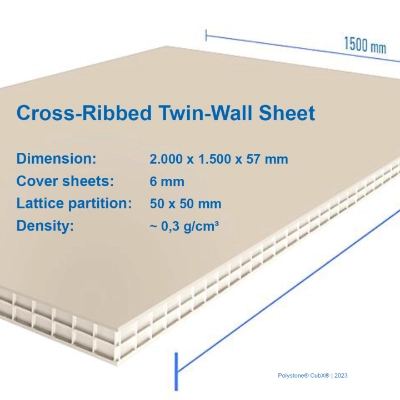

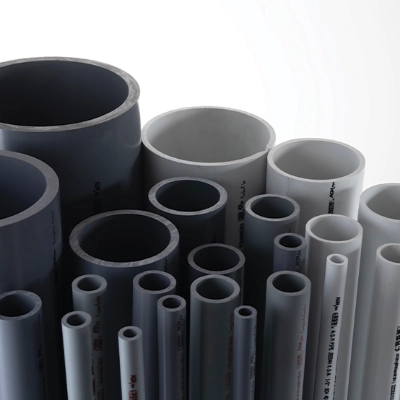

Plastic custom machined parts refer to components made from plastic materials that have undergone machining processes to achieve specific shapes, dimensions, and features. Machining is a subtractive manufacturing process where material is removed from a stock shape (rod, sheet, tube, cylinder etc) to achieve the desired form.

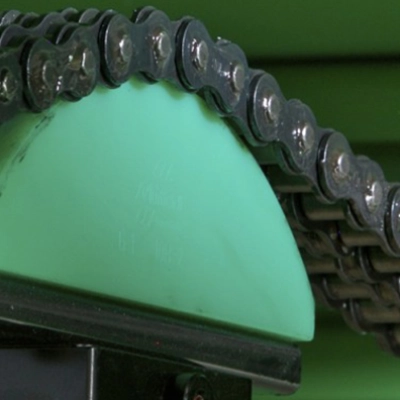

The machining process involves using tools like lathes, milling machines, routers, or CNC (Computer Numerical Control) machines to cut, shape, and finish the plastic material according to precise specifications.

Benefits of Machining compared to other plastic part manufacturing

- No Tooling – injection moulding requires expensive tooling where the design and tool making lead-times are long (3-12 months).

- Short Lead-times – generally parts can be made in days or weeks.

- No Minimum Order Quantity (MOQ) – machining is suitable for 1 off production, as well as volume on going production.

- Cost Effective – with no tooling and minimum set-up costs, these costs are eliminated (or minimised).

- Flexibility – design or dimensional changes are possible without costs incurred due to tooling changes in injection moulding.

- Compared to 3D printing (additive manufacturing), the unit production times are short, and less costly.

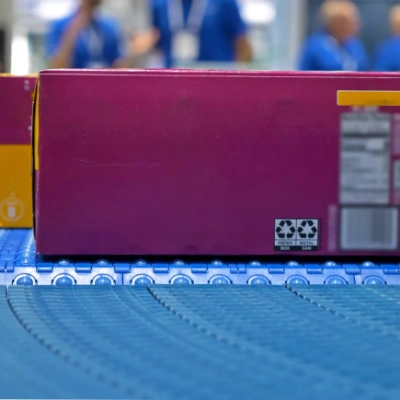

- High Quality Materials – the engineering characteristics of stock shape (Rod, sheet, tube etc) plastics are generally superior to other plastic part manufacturing techniques.

Dotmar has qualified engineers and machinists that can provide direct support with custom machined plastic parts and designs.