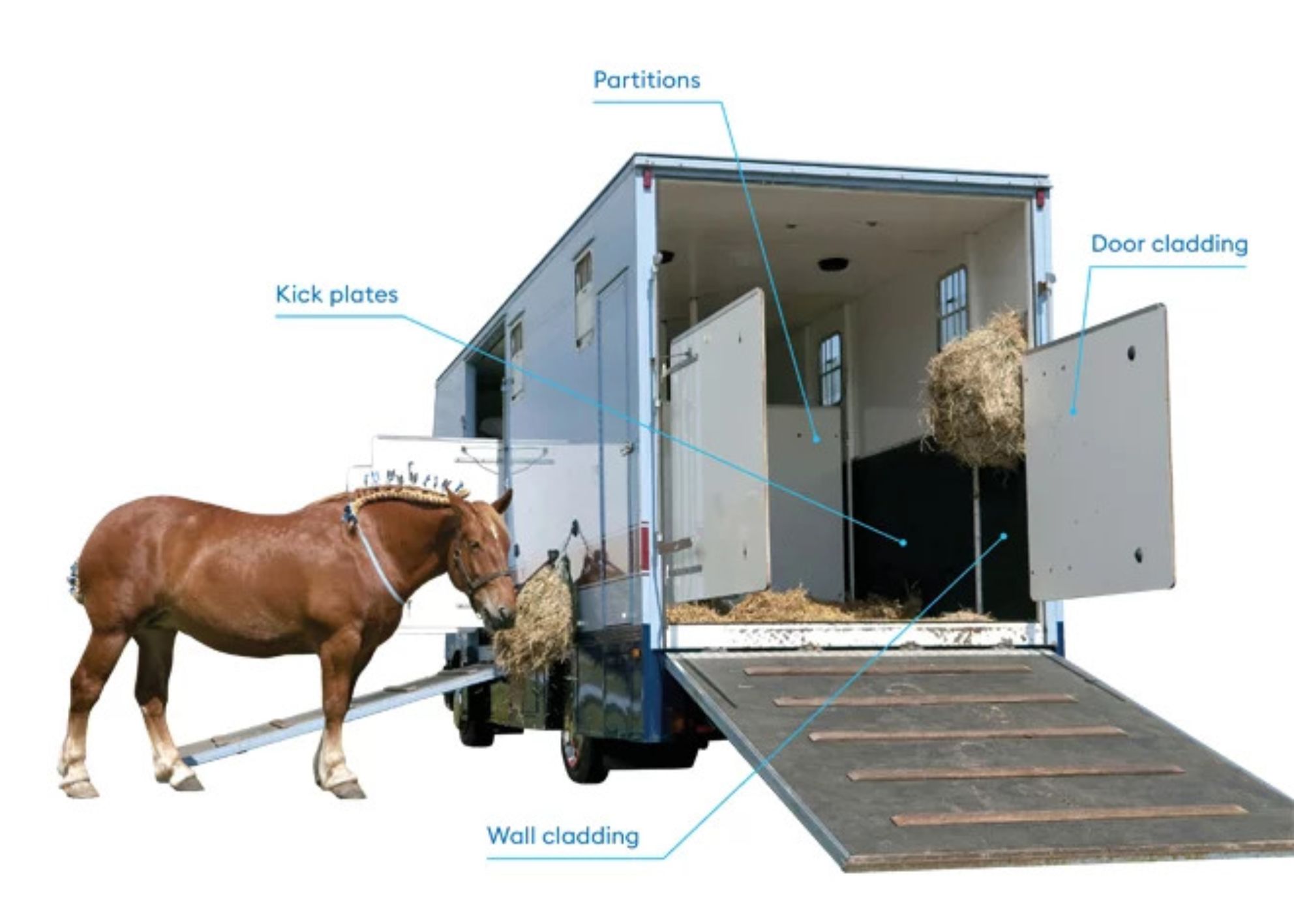

What are Plastic Enclosure Walls for Livestock?

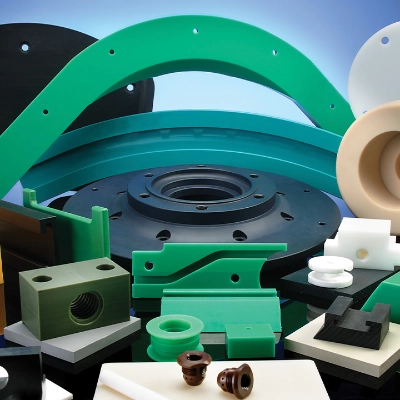

A livestock enclosure is a structure built to contain and protect animals such as cattle, sheep, horses, and pigs. The walls are typically constructed of wood, metal panels or wire mesh, but plastic wall materials are becoming increasingly more common due to the features and benefits that they bring over traditional materials.

Benefits of Plastics for livestock walls for enclosures

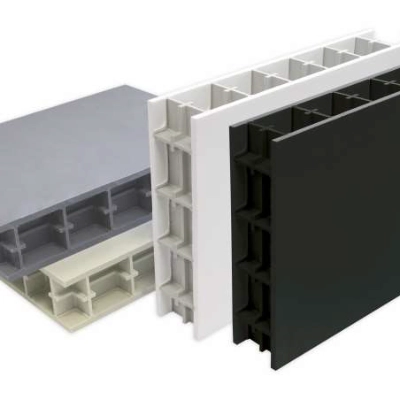

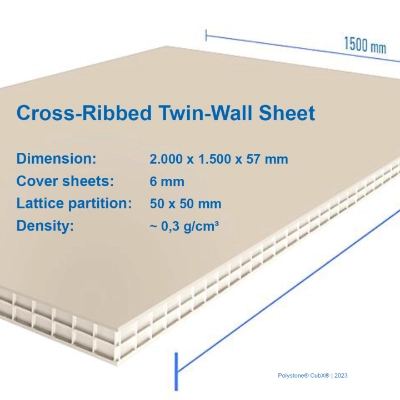

- Durability - Plastic materials, such as Foamlite (Uniboard), are highly durable and resistant to rot, corrosion, and weathering. They can withstand harsh environmental conditions better than wood and metal, leading to a longer lifespan for the enclosure.

- Low maintenance: Plastic walls require minimal maintenance compared to wood and metal. They do not need to be painted, stained, or treated regularly to prevent decay or rust. Cleaning plastic walls is often as simple as hosing them down, making them more time and cost-effective in the long run.

- Resistance to pests: Unlike wood, which can be susceptible to termite damage and other pest infestations, plastics are resistant to pests, fungi, and mould. This reduces the risk of structural damage and the need for pest control measures.

- Ease of installation: Plastic materials are lightweight and easy to work with, making them simpler and quicker to install compared to heavy wood or metal panels. This can result in lower labour costs and faster construction of livestock enclosures.

- Safety: Plastic walls are generally smoother and have fewer sharp edges compared to metal and wire mesh, reducing the risk of injury to animals. They also do not splinter like wood, further enhancing safety for both livestock and handlers.

Dotmar has qualified engineers that can provide direct support with plastic livestock enclosure wall material selection.