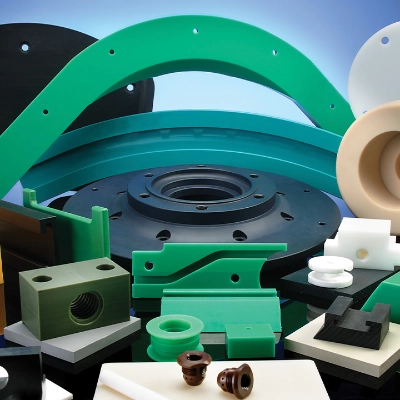

What is a Plastic Gasket?

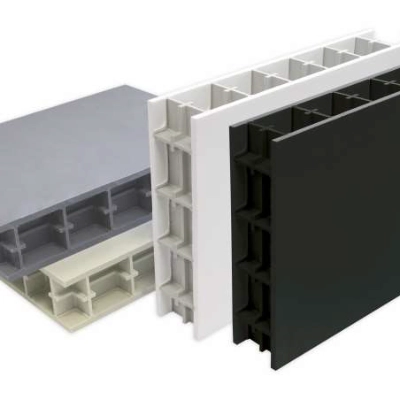

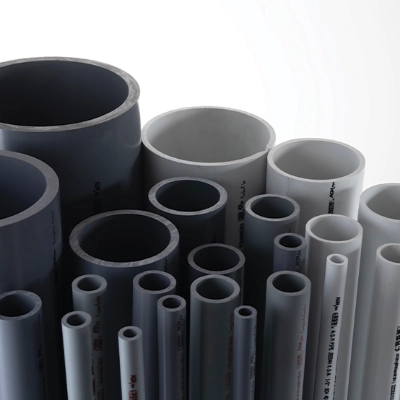

A plastic gasket is a sealing component that is designed to fit between two surfaces to prevent leakage of fluids or gases under compression. Plastic gaskets are commonly used in various industrial applications where a tight seal is necessary, such as in pumps, pipes, and manifolds. Plastic gaskets offer advantages such as resistance to corrosion, chemicals, and temperature variations, depending on the specific type of plastic used in their construction. They come in different shapes, sizes, and designs to accommodate various sealing needs.

Benefits of Custom Machined Plastic Gaskets

- Chemical Resistance - Plastic gaskets such as Tetron S are resistant to a wide range of chemicals, acids, and corrosive substances, making them suitable for applications where exposure to such materials is common.

- Temperature Resistance - Certain types of plastic gaskets can withstand extreme temperatures without losing their sealing properties, making them suitable for both high-temperature and low-temperature applications.

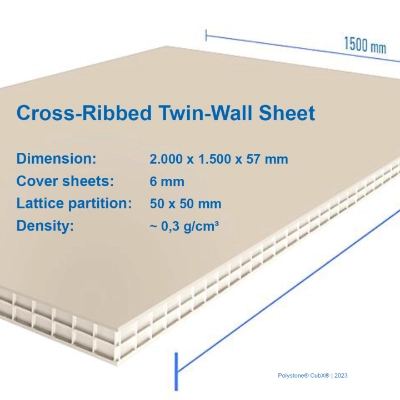

- Cost-Effectiveness - Custom machined plastic gaskets are cost-effective to manufacture especially when small quantities are required.

- Electrical Insulation - Generally plastic gaskets provide electrical insulation properties, making them suitable for sealing electrical enclosures or components where insulation is necessary.

- Durability - Engineering plastic materials can offer excellent durability and resistance to wear, tear, and deformation over time, leading to longer service life and reduced maintenance needs.

- Environmental Resistance - Plastic gaskets can be engineered to resist environmental factors such as moisture, UV radiation, and ozone, making them suitable for outdoor or harsh environment applications.

Dotmar has qualified engineers that can provide direct support with plastic material selection for gaskets.