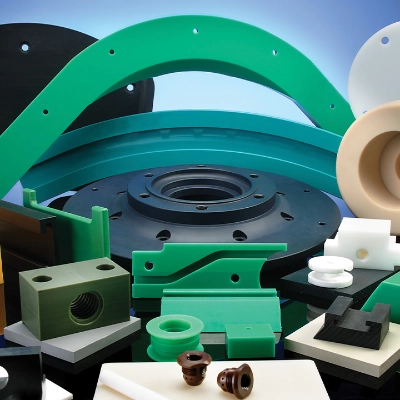

What is a Plastic Joinery & Hatch?

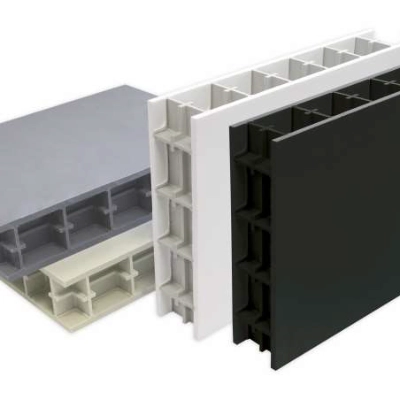

Joinery traditionally refers to the craft or trade of woodworking, creating joints to construct furniture, cabinetry and other structures. The improvements and benefits of plastics have led to plastic joinery being utilised and increasing in popularity.

Benefits of Plastic Joinery & Hatches

- Resistance to moisture and insects – Plastic materials, such as Nuvex and Uniboard/Foamlite are inherently resistant to moisture, insects, and rot. This makes them suitable for applications in humid or damp environments where wood might be susceptible to decay.

- Durability & Longevity – High-quality plastic materials are durable and have a longer lifespan, especially when exposed to harsh weather conditions or outdoor elements. Plastics are less prone to degradation from UV exposure compared to some woods.

- Low Maintenance – Plastic materials often require no maintenance. They are resistant to rot, and decay caused by UV light. Cleaning is typically straightforward, and painting is not required.

Dotmar has qualified engineers that can provide direct support with plastics for joinery and hatches.

.jpg?w=800&h=450&crop=true)