What is a Plastic Fabricated Laboratory Bench?

These benches are typically made of materials that are resistant to chemicals, heat, and physical wear. The surface is usually smooth and easy to clean, allowing researchers to work with different substances without contamination.

Laboratory benches are equipped with features such as built-in sinks. They provide a controlled environment for scientists and researchers to perform experiments, analyse samples, and carry out various scientific procedures.

Benefits of Plastic Fabricated Laboratory Benches

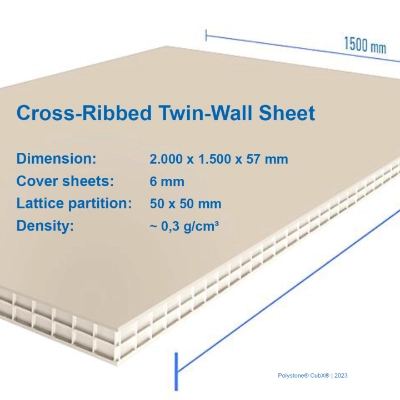

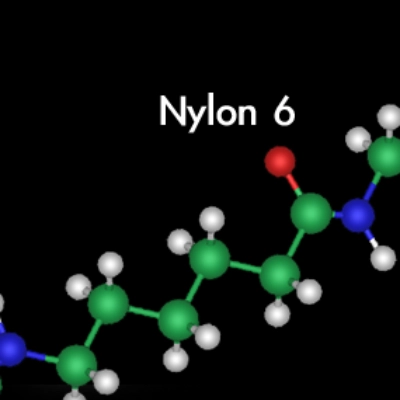

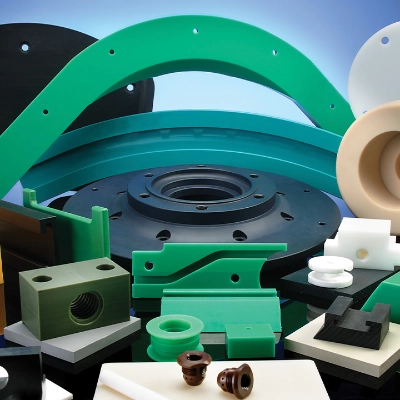

- Chemical Resistance – Plastics such as Polystone P and Trovidur EC-N have excellent chemical resistance, generally better than other traditional materials that are used for Laboratory benches.

- Easy to Customise – plastic fabricated benches, and other laboratory equipment, can easily and cost effectively be customised to suit individual requirements and fitment.

- East to Clean – Plastic surfaces are typically smooth and non-porous, making them easy to clean and disinfect. This is crucial in laboratories where maintaining a sterile and contamination-free environment is essential.

- Durability – High-quality plastics are durable and can withstand physical wear and tear. They are less prone to chipping, scratching, or denting compared to some other materials, providing a longer lifespan for the laboratory furniture.

- Lightweight - Plastic benches are generally lighter than their metal or wood counterparts. This can be beneficial when flexibility is needed in laboratory layout or when benches need to be moved or reconfigured.

- Cost Effective - Plastic fabrication can be a cost-effective option compared to other materials. This can be especially important for laboratories with budget constraints.

Dotmar has qualified engineers that can provide direct support with plastic material selection for fabricated laboratory benches and equipment.