What is a Plastic Outrigger Plate?

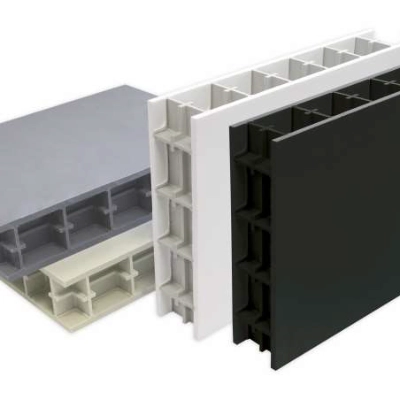

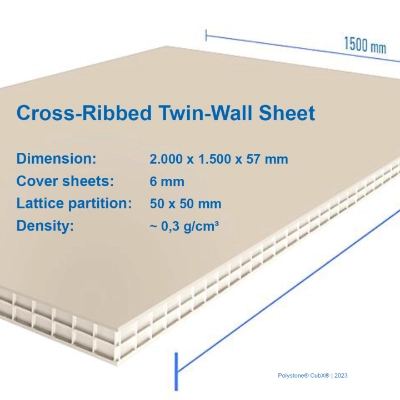

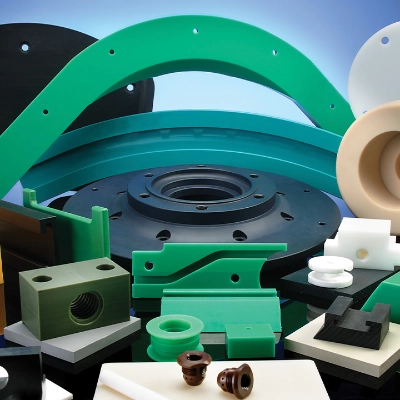

An outrigger plate is a specialised base support used in conjunction with outriggers on cranes and other heavy equipment. It's a flat, sturdy platform typically made from durable materials like plastic, wood, or metal. These pads are placed under the outrigger legs of the crane to provide a larger and more stable surface area, distributing the weight over a broader space.

Benefits of Plastic Outrigger Plates, Pads or Feet

- Lightweight - Plastic outrigger plates are lighter than steel plates, making them easier to handle and transport. This characteristic can contribute to quicker setup times and increased efficiency on job sites.

- Corrosion Resistance - Plastic plates are resistant to corrosion caused by exposure to moisture, chemicals, or harsh weather conditions. This resistance ensures a longer lifespan compared to steel, which may rust over time.

- Non-Conductive - Plastic outrigger plates are non-conductive, unlike metal alternatives. This feature can be advantageous in situations where electrical hazards are a concern, reducing the risk of electrical conductivity.

- Impact Resistance - The appropriately selected plastic material for outrigger plates offer excellent impact resistance. They can withstand heavy loads and rough handling without denting or deforming, providing reliable stability for the crane.

- Environmentally Friendly - Plastic outrigger plates can be made from recyclable materials, contributing to environmentally conscious practices on construction sites.

Dotmar has qualified engineers that can provide direct support with the appropriate material selection for plastic outrigger plates, including conducting calculations and reports.

.jpg?w=800&h=450&crop=true)