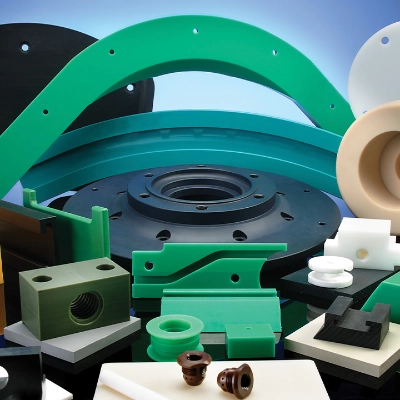

What is a Plastic Wear Strip?

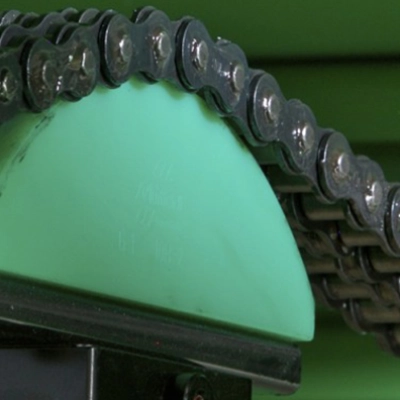

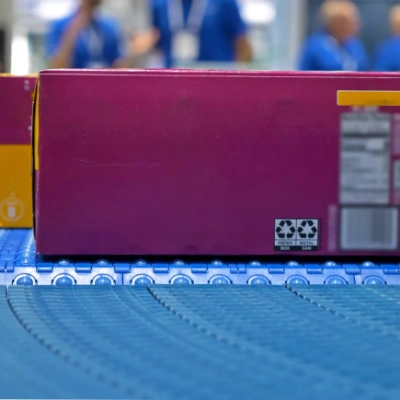

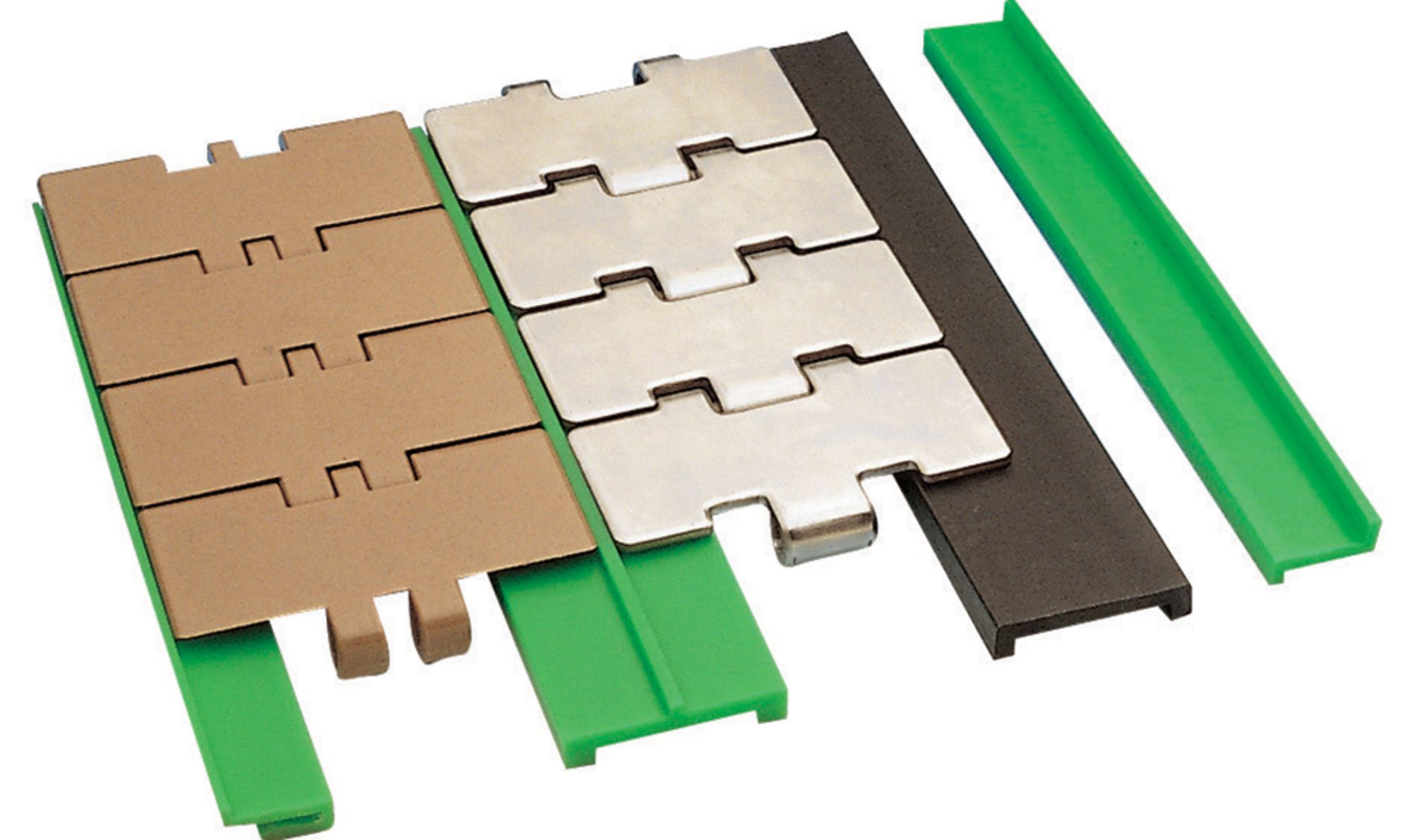

A wear strip, sometimes referred to as a wear bar or wear plate, is a component used in various machinery and equipment to reduce friction, prevent damage, and extend the life of the machinery and components. It's typically made from a durable material like plastic or metal, and is placed in areas that experience frequent contact, rubbing, or abrasion. For example, roller chain in long lengths or section are supported by a Polystone Ultra Wear Strip to prevent the chain rubbing and damaging other equipment, as well as extending the life of the chain.

Benefits of Plastic Wear Strips

- Reduced Friction: The lower co-efficient of friction of plastics reduces wear between moving parts and drive forces and energy, compared to metal wear faces.

- Noise Reduction: The lower density and lower hardness, suppresses vibration and noise.

- Corrosion Resistance: Plastics can be resistant to certain chemicals and corrosion, making them suitable for use in environments where metal components might corrode.

- Lightweight: Compared to metal alternatives, plastic wear strips are often lighter, which can be beneficial in applications where weight is a concern.

- Cost-Effective: Plastic wear strips are generally more cost-effective than metal alternatives, both in terms of material costs and ease of manufacturing.

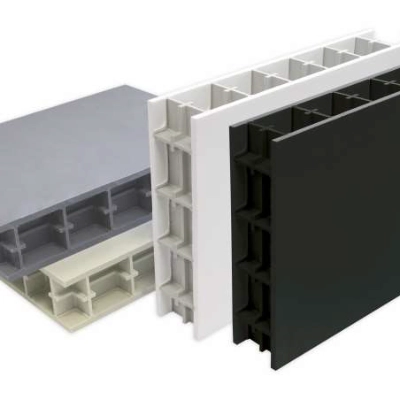

- Customizable: Plastics are more easily shaped, allowing for customization to fit specific shapes and sizes required for different applications.

- Maintenance Reduction: They can extend the life of equipment by protecting against wear, reducing the need for frequent replacements, maintenance and lubrication.

- Electrical Insulation: Plastics offer electrical insulation properties, making them suitable for use in electrical applications.

Dotmar has qualified engineers that can provide direct support with plastic wear strip designs, including conducting calculations.

.bmp?w=800&h=450&crop=true)

%20-%20non-depp.jpg?w=800&h=450&crop=true)